Cleavage and Deprotection Systems

Enhance oligo production safety and efficiency

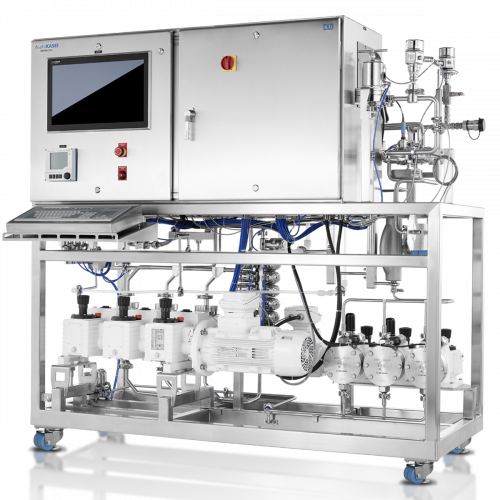

C&D Systems

Streamline this key unit operation in oligonucleotide manufacturing with an intuitive system from our Cleavage and Deprotection (C&D) family of products. Our mid- to large-scale C&D Systems allow you to automate the cleavage and deprotection steps while increasing your synthesis capacity by freeing up the oligosynthesizer to focus on its core functions. Available in a broad range of flow rates, C&D Systems are designed to accommodate both DNA and RNA processes.

Need a Quote?

We Can HelpBuilt For You.

Post-synthesis, the crude oligonucleotide must be cleaved from the solid support and conditioned for further downstream processing steps. Our C&D Systems are designed to accommodate both DNA and RNA processes with numerous in-process controls to automate steps.

Key Features

- Automated system designed and purpose-built for cleavage and deprotection, freeing up your synthesizer.

- Advanced process controls with monitoring and control by UV, conductivity, pressure, temperature, flow rate or volume.

- Available with deprotection vessels for a turnkey solution.

- OCELOT™ System Control – our latest universally plant-compatible automation software.

- Chemically compatible with HF or other chemicals as required and rated for hazardous area use.

- Customizable to meet your process and facility requirements.

Asahi Kasei Bioprocess C&D Systems can be designed for chemical compatibility with HF as needed. Systems are available with integrated deprotection vessels, or alternatively can be used with your existing vessel.

Breadth of Configurations

| Catalog No. | Deprotection Vessel Working Volume | Pressure Rating | Metering Pump Flow Rate | Material of Construction |

| CD020 | 20 L | 6 bar | 6 to 180 L/h | 316L SS |

| CD100 | 100 L | 6 bar | 20 to 600 L/h | 316L SS |

| CD350 | 350 L | 6 bar | 48 to 2000 L/h | 316L SS |

C&D Systems can be customized to meet specific user requirements for your manufacturing process:

- Second metering pump and flowmeter constructed of Hastelloy

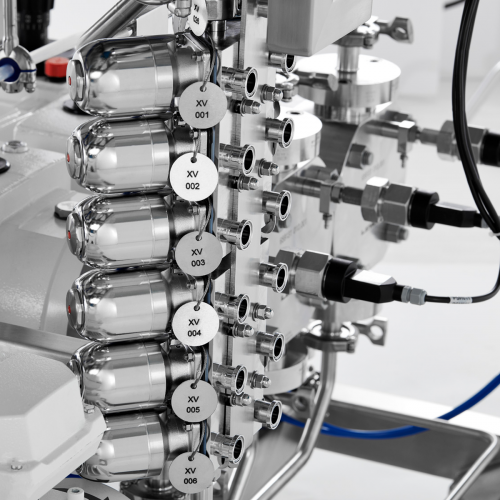

- Upgrade from eight (8) to twelve (12) main inlet ports

- Upgrade to column forward flow, backflow and bypass modes

- Jacketed deprotection vessel (user-specified volume)

- Upgrade from three (3) to four (4) outlet ports including recirculation

- Local panel-mount Human-Machine Interface (HMI)