Liquid Chromatography Systems

Reproducible gradient formation and cutting-edge software for today’s preparative- to production-scale purifications.

Flash LC Systems

For rapid cleanup of small molecules using 40 to 63 μm or for larger irregular silica gels, Asahi Kasei Bioprocess offers industrial Flash LC Systems. These economical large-scale purification systems are designed for both normal-phase and reverse-phase applications that are operated at pressures up to 10 bar.

Need a Quote?

We Can HelpGradient Mixing Technologies

Standard Flash LC Systems are isocratic. However, a selection of proprietary and patent- pending gradient mixing technologies to permit you to reproducibly separate your target therapeutic at large-scale, whether it be via reverse-phase or normal phase gradient elutions.

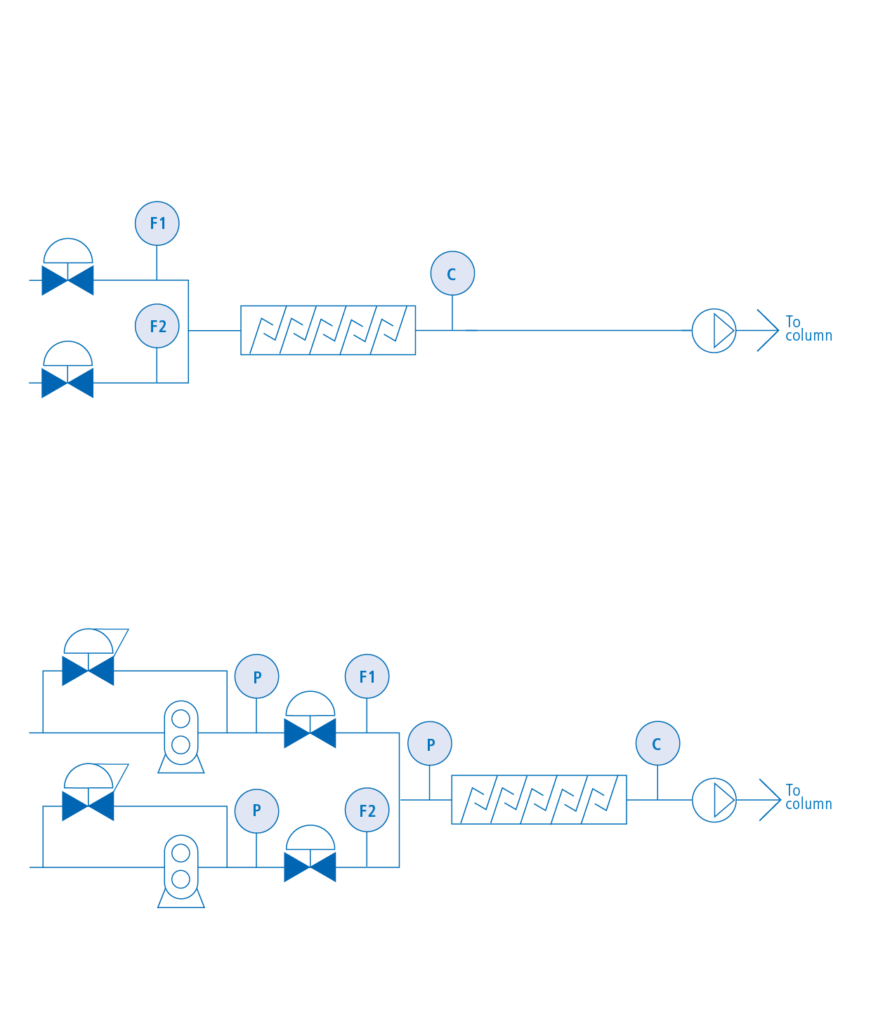

Low Pressure Gradient Mixing

- Control valves proportion eluents

- Mixing is on low pressure side of pumps

Classic:

Controller type: Adaptive PAT control or ow control Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

Enhanced:

Controller type: Adaptive PAT control or ow control Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

High Pressure Gradient Mixing

• Pumps proportion eluents

• Mixing is on high pressure side of pumps

Controller type: Flow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

Industrial Flow Paths

Since small molecules and other intermediates that require Flash LC Systems are purified in organic solvents, our cost-effective industrial design is well-suited for Flash LC Systems.

| Feature | Industrial |

|---|---|

| Eluents | Mainly organic solvents |

| Process connections: Inlets/outlets | TC |

| Process connections: Internal | NPT & compression |

| Wetted MOC | 316, 316Ti, 316L |

| Surface finish spec | None |

| Electropolish | No |

| Piping | Hand welds |

| Piping documentation | Material CofC only |

| Low point drains | No |

| Elastomers | PTFE, FFKM, FEP |

| Elastomer cert | N/A |

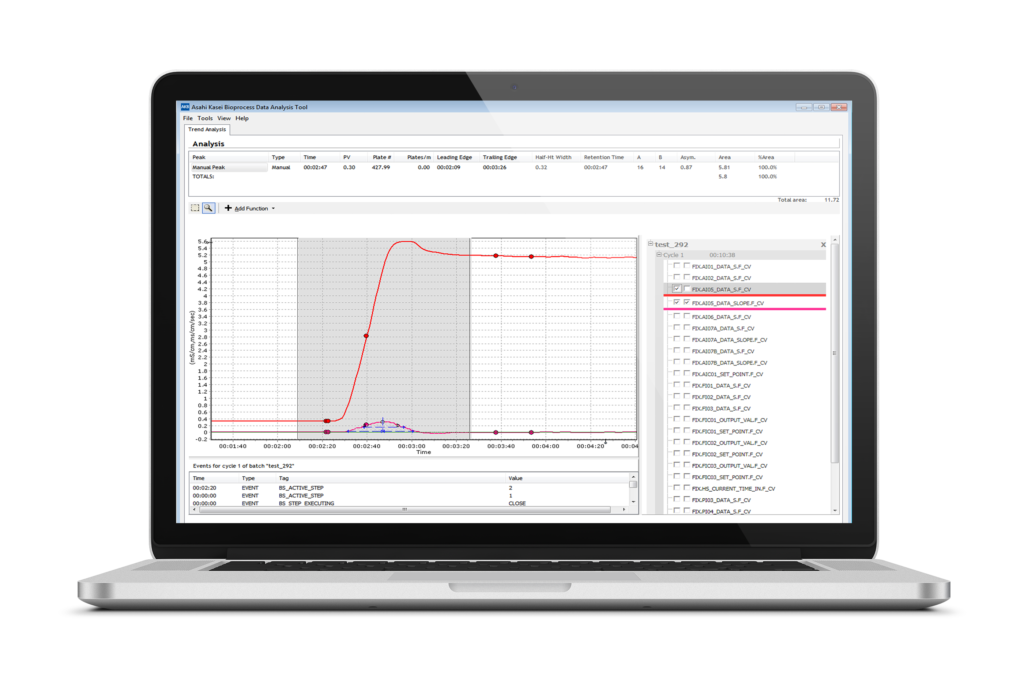

Software Designed For You

Off-the-shelf chromatography systems may provide familiar software, but have rigid hardware constraints; conversely, systems with customized hardware are typically burdened with cumbersome and dated software. You no longer have to compromise.

Freedom of Customization

Your unique purification processes or multi-product applications may require an Flash LC System that is different than the standard offerings. Our team of artisan engineers and designers will craft you a customized solution based on our standard Flash LC System platform..

Features include:

- Number of inlet ports or fractions

- End-of-stream air sensors

- Pre-filters

- Sample injection loops

- Software customization

- Hazardous area ratings (NFPA and ATEX)

- Modified footprints to fit into tight spaces and within fume hoods

Equipment designed to respect your manufacturing needs

Product Options

| Catalog No. | Flow Rate Range | Pressure Rating | Typical DAC Column Pairing |

| LPC360 | 36 – 360 L/h | 10 bar | 30 – 45 cm i.d. |

| LPC600 | 60 – 600 L/h | 7.5 bar | 40 – 60 cm i.d. |

| LPC900 | 90 – 900 L/h | 7.5 bar | 60 – 100 cm i.d. |