MOTIV™ Inline Buffer Formulation

Meet the technology that is truly built for you and is designed to move you beyond your downstream processing bottlenecks.

MOTIV™ 3

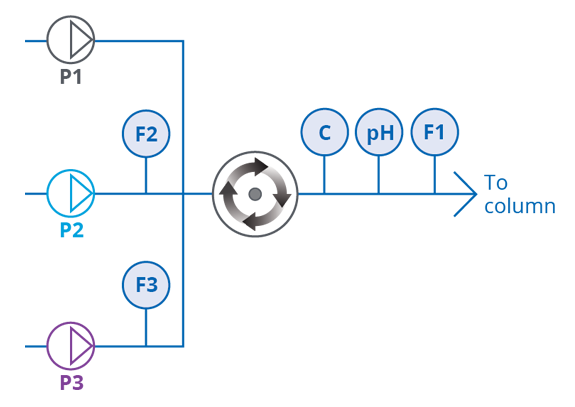

Designed to fit within tighter space and budget constraints, our patented 3-pump IBF Systems leverage process analytical technology (PAT) to generate precise and reproducible buffers for a consistent yield and recovery of your biologic product.

1,000 L/h

Clinical Manufacturing

5,000 - 10,000 L/h

Large Scale Manufacturing

15,000 L/h

Extra Large Scale Manufacturing

Built For You

Meet the technology that is truly built for you and is designed to move you beyond your downstream processing bottlenecks.

Driven by our patented Pro-Yield™ inline recirculation blender technology, our family of 3-Pump, 5-Pump and custom inline buffer formulation systems can meet almost any space, cost or performance need.

Patented Pro-Yield™ Recirculation Blender Technology

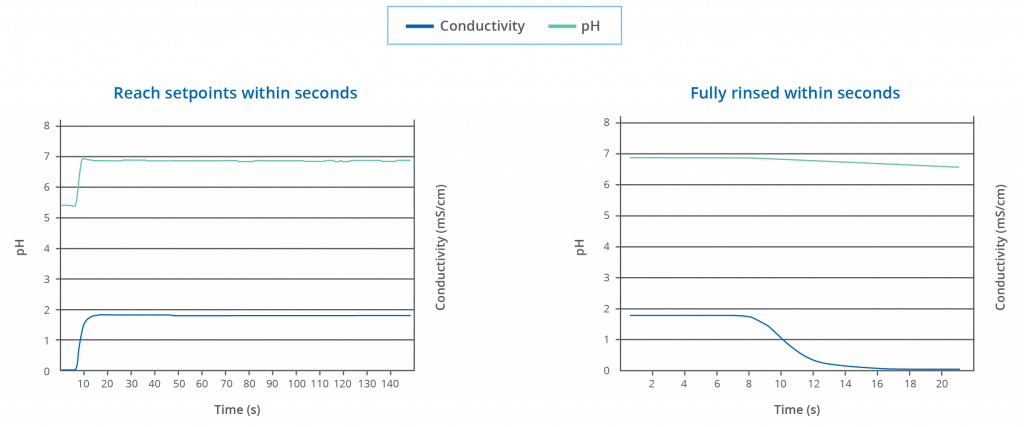

All MOTIV systems include our patented, Pro-Yield recirculation blending technology to shorten the buffer adjustment response rate. The dynamic, single-pass mixer efficiently blends your liquid streams inline – regardless of flow rate or viscosity – to allow for a faster setpoint target and faster washout volumes.

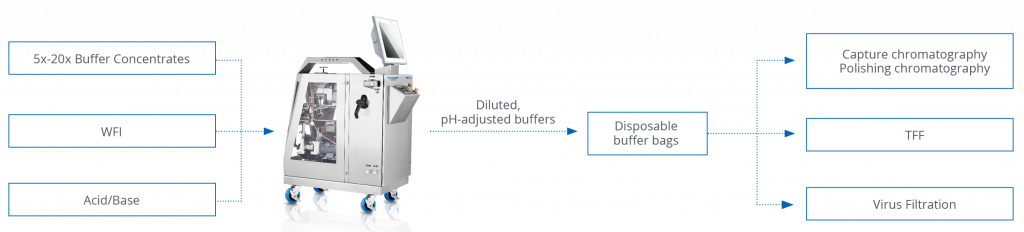

Efficient Buffer Production

With MOTIV 3, you can leverage stock buffer concentrates and pH modifiers to produce high-quality buffers on demand, within as short as 15 seconds from system start-up. After use, the system can be rinsed down in under a minute.

Buffers On-Demand

Continuous Processes

Create subroutines and stack recipe segments to produce multiple process buffers unattended and sequentially, just-in-time to feed continuous chromatography systems.

THOUSANDS

Sq ft of GMP floor space saved

1000+ HRS

Saved in buffer prep

MILLIONS

Liters of buffers produced

Product Options

| MOTIV 310 | MOTIV 350 | MOTIV 3100 | MOTIV 3150 |

| 60 — 1000 L/h | 500 — 5000 L/h | 1000 – 10,000 L/h | 1500 – 15,000 L/h |

| Mobile console format | Space-saving skid format | Space-saving skid format | |

| Clinical scale manufacturing | Large scale manufacturing | Large scale manufacturing | |

| Up to 20x dilution | Up to 20x dilution | Up to 20x dilution | |

| 770 mm W x 1500 mm D x 1610 mm H | 1990 mm W x 1220 mm D x 1880 mm H | 1990 mm W x 1530 mm D x 1880 mm H | |

Note: Dimensions are approximate. Customized systems for unique applications are also available.

OCELOT™ System Control

Each MOTIV™ is outfitted with the latest in automation capabilities – OCELOT™ – bringing intuitive configuration in a universally compatible format. OCELOT can integrate and/or interface with your plant-wide control system – allowing for far-reaching data collection and analysis.

- Designed to be simple and straightforward

- OPC-ready architecture, with remote method configuration and batch review

- Point-of-use scale up/scale down