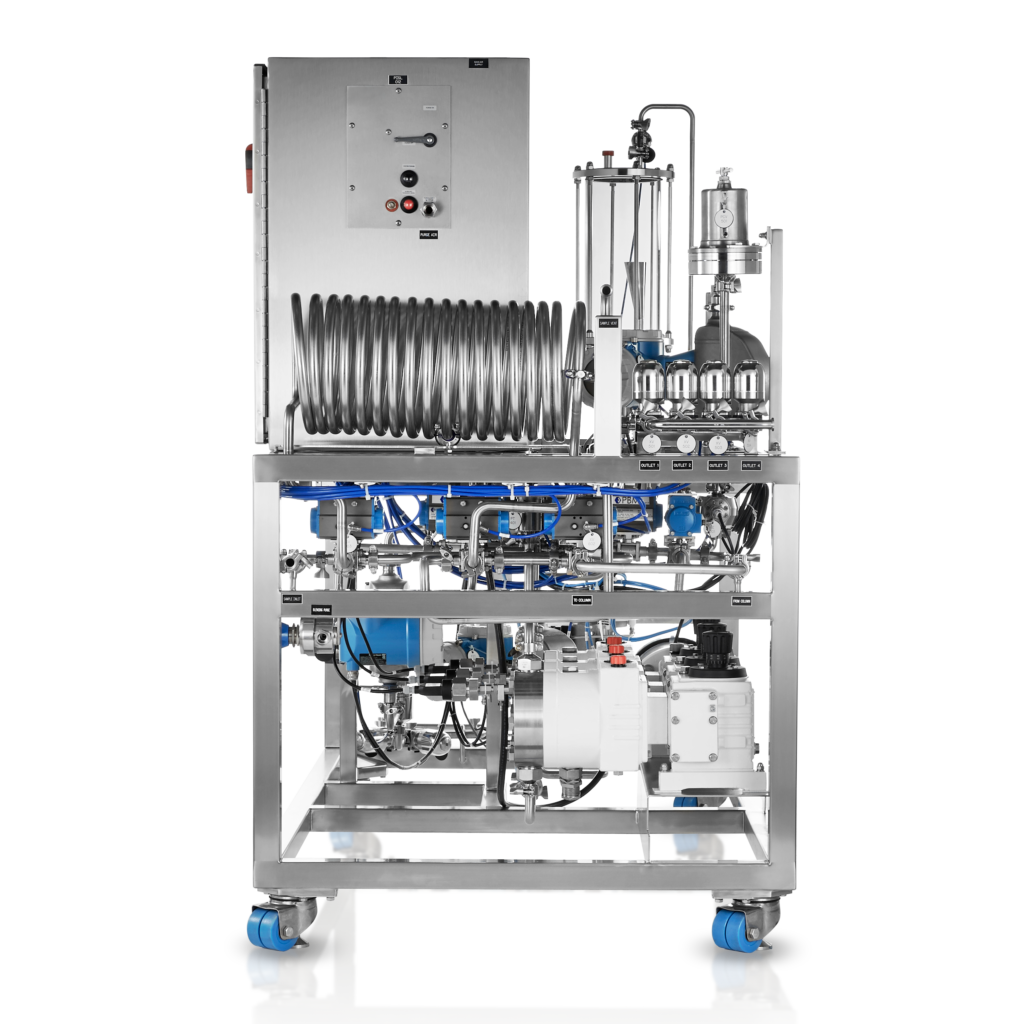

Liquid Chromatography Systems

Reproducible gradient formation and cutting-edge software for today’s preparative- to production-scale purifications.

HPLC Systems

Classic small molecule and small protein purification processes utilizing 10 to 15 μm chromatography media will generate backpressures of 70 to 100 bar. Such applications typically require linear gradients to achieve the desired product purity. Our HPLC Systems meet the required pressure rating while offering an array of flexible gradient technology options to fit your needs—whether it is normal phase, reverse-phase or chiral chromatography.

Need a Quote?

We Can HelpGradient Mixing Technologies

We offer a selection of proprietary and patent-pending gradient mixing technologies to permit you to reproducibly separate your target therapeutic at large-scale, whether it be via ion exchange or reverse-phase or normal phase gradient elutions.

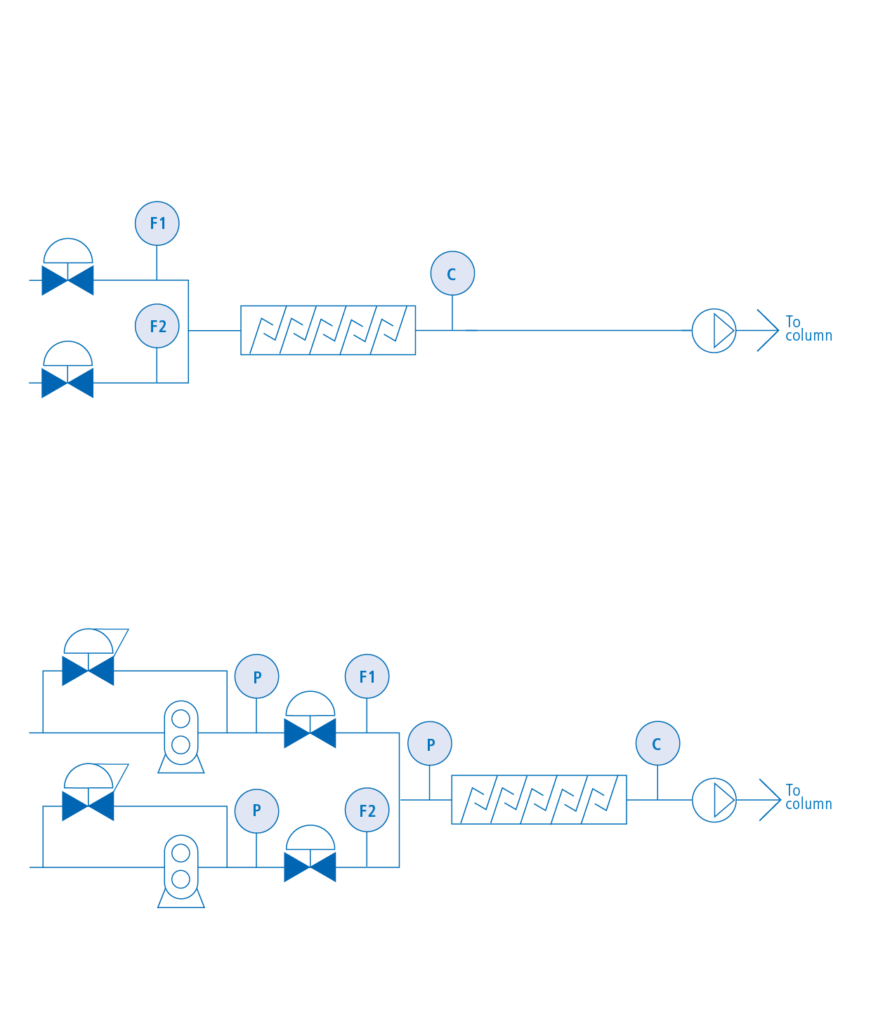

Low Pressure Gradient Mixing:

- Control valves proportion eluents

- Mixing is on low pressure side of pumps

Classic:

Controller type: Adaptive PAT control or flow control

Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

Enhanced:

Controller type: Adaptive PAT control or ow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

High Pressure Gradient Mixing:

- Pumps proportion eluents

- Mixing is on high pressure side of pumps

Controller type: Flow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

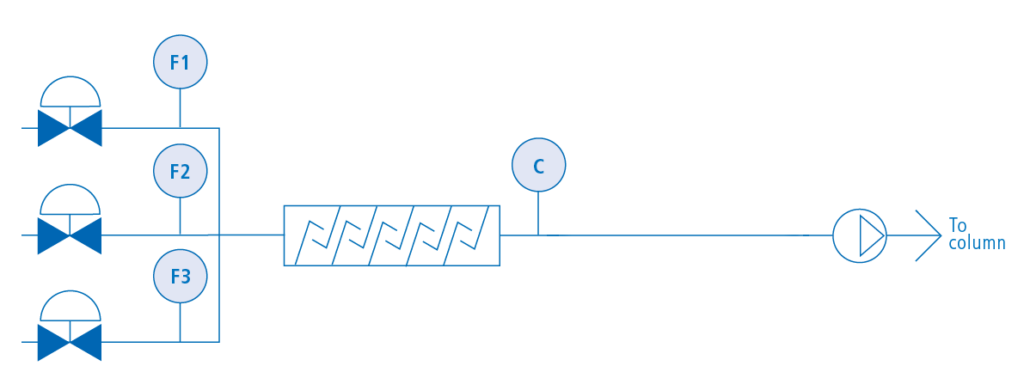

Ternary Low Pressure Gradient Mixing:

- Three control valves proportion eluents

- Mixing is on low pressure side of pumps

- Ideal for combination aqueous/organic elutions

Controller type: Adaptive PAT control or ow control

Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

Industrial, Sanitary or Hygienic Flow Paths

For oligonucleotide or microbial-derived protein purifications that mainly utilize aqueous mobile phases with limited use of organics, or for highly potent active pharmaceutical ingredient (HP-API) purifications where minimized system hold-up is desired, our sanitary or hygienic flow paths are attractive options. Alternatively, our industrial flow path is the most cost-effective for small molecules.

| Feature | Industrial | Sanitary ≤ 0.6 µm | Hygienic ≤ 0.5 µm |

| Eluents | Mainly organic solvents | Organic solvents, aqueous buffers | Organic solvents, aqueous buffers |

| Process connections | Inlets/outlets: TC | Inlets/outlets: TC | Inlets/outlets: TC |

| Process connections | Internal: NPT & compression | Internal: TC or VCR | Internal: TC |

| Wetted MOC | 316, 316Ti, 316L | 316, 316Ti, 316L | 316L |

| Surface finish spec | None | SO.6 pm internal | sO.S pm internal |

| Electropolish | No | Yes, except main pump and ball valves | Yes, throughout |

| Piping | Hand welds | Orbital welds | Orbital welds |

| Piping documentation | Material CofC only | Material certs, weld maps, weld logs | Material certs, weld maps, weld logs |

| Low point drains | No | No | Yes |

| Elastomers | PTFE, FFKM, FEP | PTFE, FFKM, FEP | PTFE, FFKM, FEP |

| Elastomer certs | N/A | USP Class VI / BSE-TSE-free | USP Class VI / BSE-TSE-free |

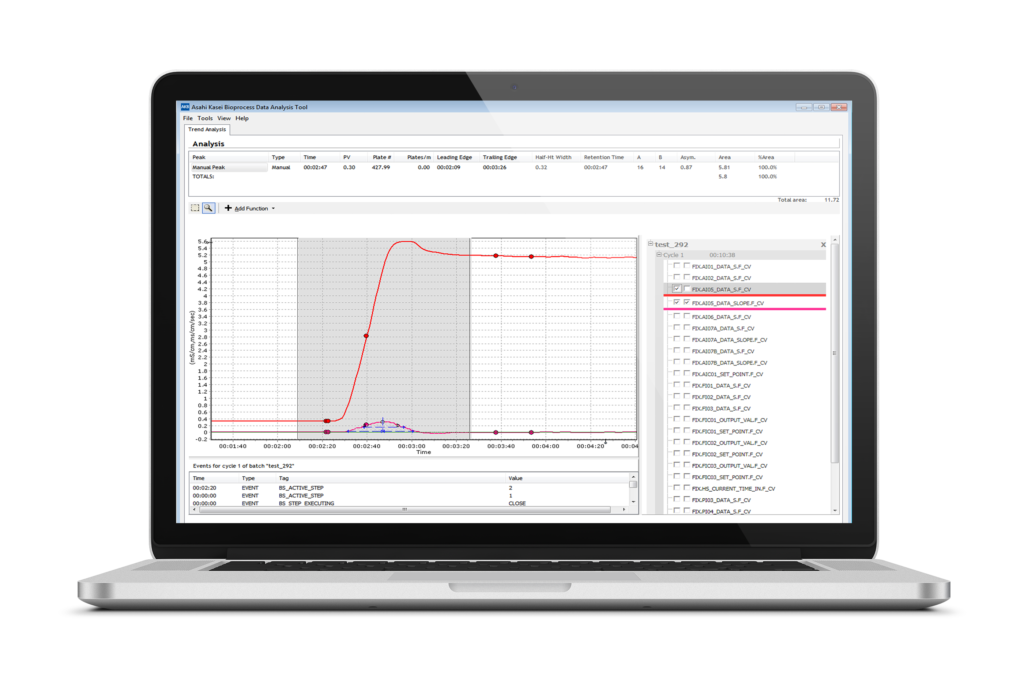

Software Designed For You

Off-the-shelf chromatography systems may provide familiar software, but have rigid hardware constraints; conversely, systems with customized hardware are typically burdened with cumbersome and dated software. You no longer have to compromise.

Freedom of Customization

Your unique purification processes or multi-product applications may require an HPLC System that is different than the standard offerings. Our team of artisan engineers and designers will craft you a customized solution based on our standard HPLC System platform.

Features include:

- Number of inlet ports or fractions

- Spill-free connections

- Sample pumps

- End-of-stream air sensors

- Pre-filters

- Sample injection loops

- Heat exchangers

- Software customization

- Hazardous area ratings (NFPA and ATEX)

- Modified footprints to fit into tight spaces and within fume hoods

Equipment designed to respect your manufacturing needs

Product Options

| Catalog No. | Flow Rate Range | Pressure Rating | Typical DAC Column Pairing |

| HPC060 | 6-60 L/h | 100 bar | 6- 15 cm i.d. |

| HPC120 | 12 -120 L/h | 100 bar | 7.5-20 cm i.d. |

| HPC180 | 18-180 L/h | 70 bar | 10-20 cm i.d. |

| HPC240 | 24- 240 L/h | 70 bar | 10-30 cm i.d. |

| HPC360 | 36 – 360 L/h | 70 bar | 15-40 cm i.d. |

| HPC600 | 60 – 600 L/h | 70 bar | 20-45 cm i.d. |

| HPC900 | 90 – 900 L/h | 70 bar | 30 – 60 cm i.d. |

| HPC1K2 | 120- 1200 L/h | 70 bar | 30-80 cm i.d. |

| HPC2K4 | 240- 2400 L/h | 70 bar | 40- 100 cm i.d. |