Liquid Chromatography Systems

Reproducible gradient formation and cutting-edge software for today’s preparative- to production-scale purifications.

MPLC Systems

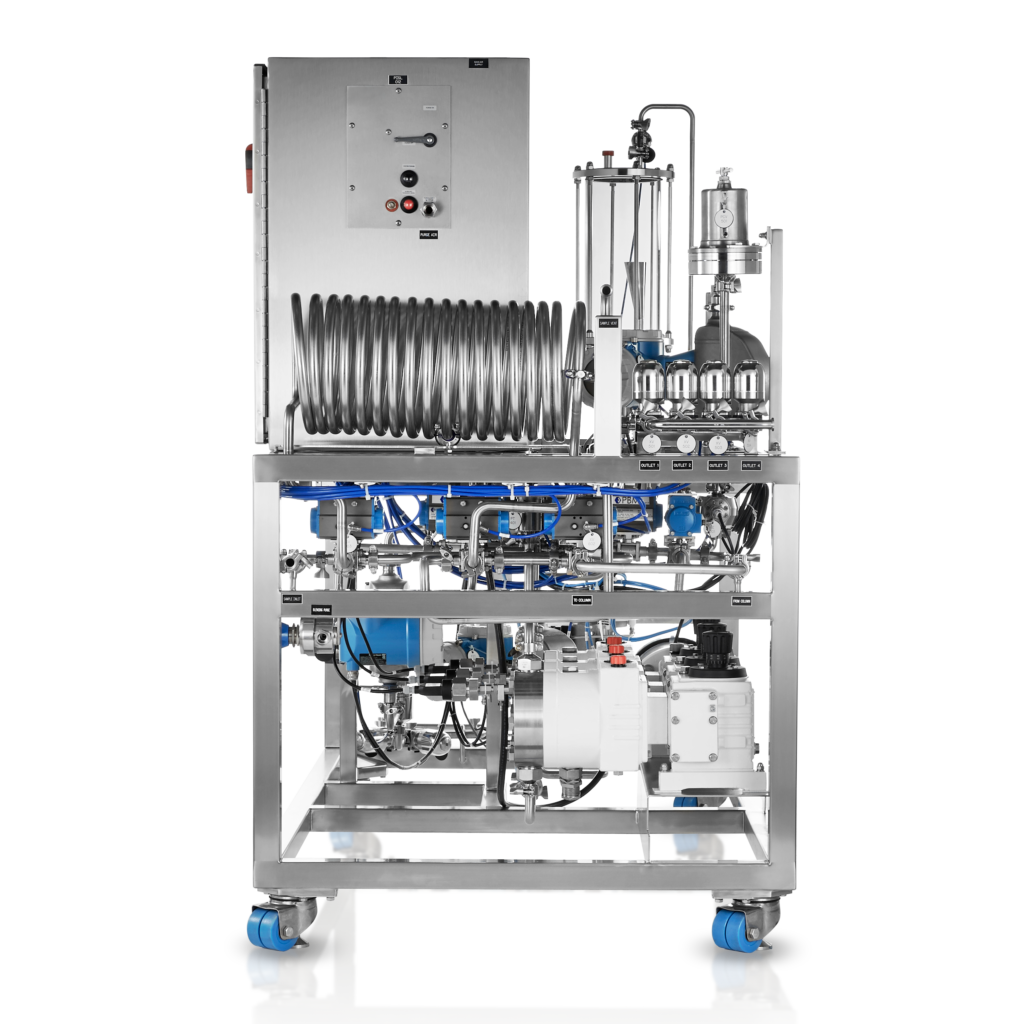

Many mid-sized therapeutics in the 4 to 15 kDa range, such as microbial- derived proteins and oligonucleotides, are purified using 15 to 40 μm chromatography media. Such processes generate higher backpressures than can be accommodated by a typical 6 or 10 bar system but don’t require the pressure rating and upfront capital cost of traditional preparative HPLC. For over a decade, Asahi Kasei Bioprocess has been a leader in 20 bar MPLC Systems for these applications.

Need a Quote?

We Can HelpGradient Mixing Technologies

We offer a selection of proprietary and patent-pending gradient mixing technologies to permit you to reproducibly separate your target therapeutic at large-scale, whether it be via ion exchange or reverse-phase gradient elutions.

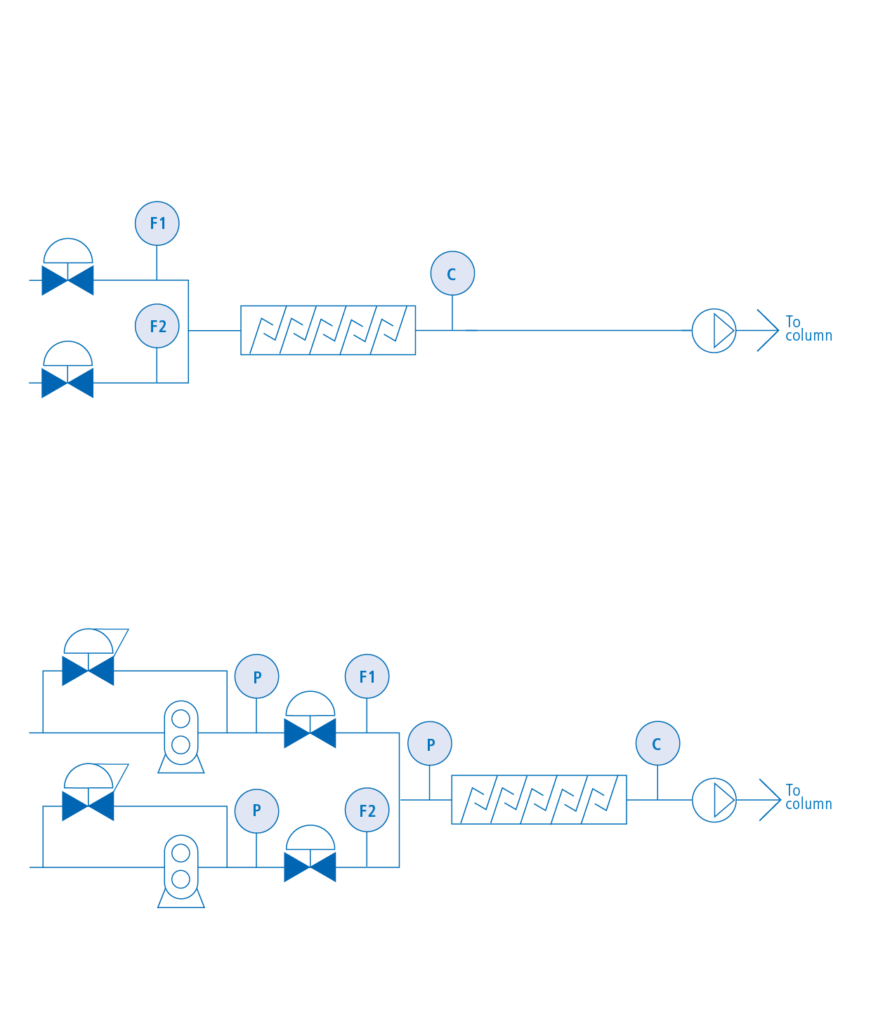

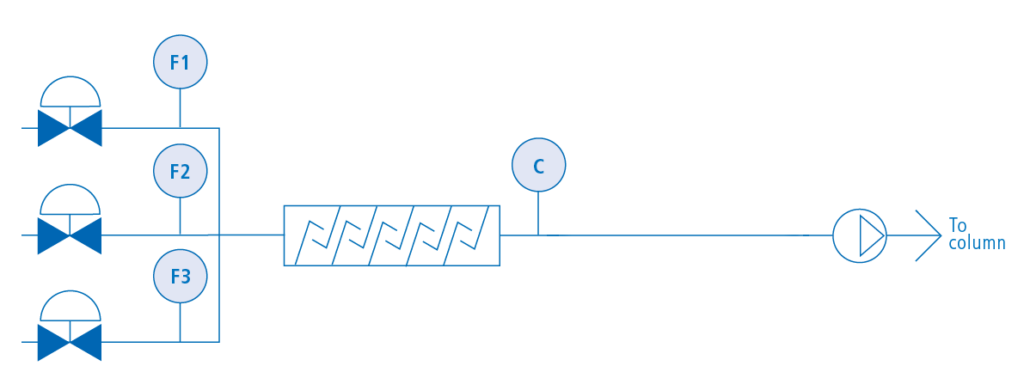

Low Pressure Gradient Mixing:

- Control valves proportion eluents

- Mixing is on low pressure side of pumps

Classic:

Controller type: Adaptive PAT control or flow control

Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

Enhanced:

Controller type: Adaptive PAT control or ow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

High Pressure Gradient Mixing:

- Pumps proportion eluents

- Mixing is on high pressure side of pumps

Controller type: Flow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

Ternary Low Pressure Gradient Mixing:

- Three control valves proportion eluents

- Mixing is on low pressure side of pumps

- Ideal for combination aqueous/organic elutions

Controller type: Adaptive PAT control or ow control

Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

Industrial, Sanitary or Hygienic Flow Paths

For oligonucleotide or microbial-derived protein purifications that mainly utilize aqueous mobile phases with limited use of organics, or for highly potent active pharmaceutical ingredient (HP-API) purifications where minimized system hold-up is desired, our sanitary or hygienic flow paths are attractive options. Alternatively, our industrial flow path is the most cost-effective solution.

| Feature | Industrial | Sanitary ≤ 0.6 µm | Hygienic ≤ 0.5 µm |

| Eluents | Mainly organic solvents | Organic solvents, aqueous buffers | Organic solvents, aqueous buffers |

| Process connections | Inlets/outlets: TC | Inlets/outlets: TC | Inlets/outlets: TC |

| Process connections | Internal: NPT & compression | Internal: TC or VCR | Internal: TC |

| Wetted MOC | 316, 316Ti, 316L | 316, 316Ti, 316L | 316L |

| Surface finish spec | None | SO.6 pm internal | sO.S pm internal |

| Electropolish | No | Yes, except main pump and ball valves | Yes, throughout |

| Piping | Hand welds | Orbital welds | Orbital welds |

| Piping documentation | Material CofC only | Material certs, weld maps, weld logs | Material certs, weld maps, weld logs |

| Low point drains | No | No | Yes |

| Elastomers | PTFE, FFKM, FEP | PTFE, FFKM, FEP | PTFE, FFKM, FEP |

| Elastomer certs | N/A | USP Class VI / BSE-TSE-free | USP Class VI / BSE-TSE-free |

Freedom of Customization

Your unique purification processes or multi-product applications may require an MPLC System that is different than the standard offerings. Our team of artisan engineers and designers will craft you a customized solution based on our standard MPLC System platform.

Features include:

- Number of inlet ports or fractions

- Spill-free connections

- Sample pumps

- End-of-stream air sensors

- Pre-filters

- Sample injection loops

- Heat exchangers

- Software customization

- Hazardous area ratings (NFPA and ATEX)

- Modified footprints to fit into tight spaces and within fume hoods

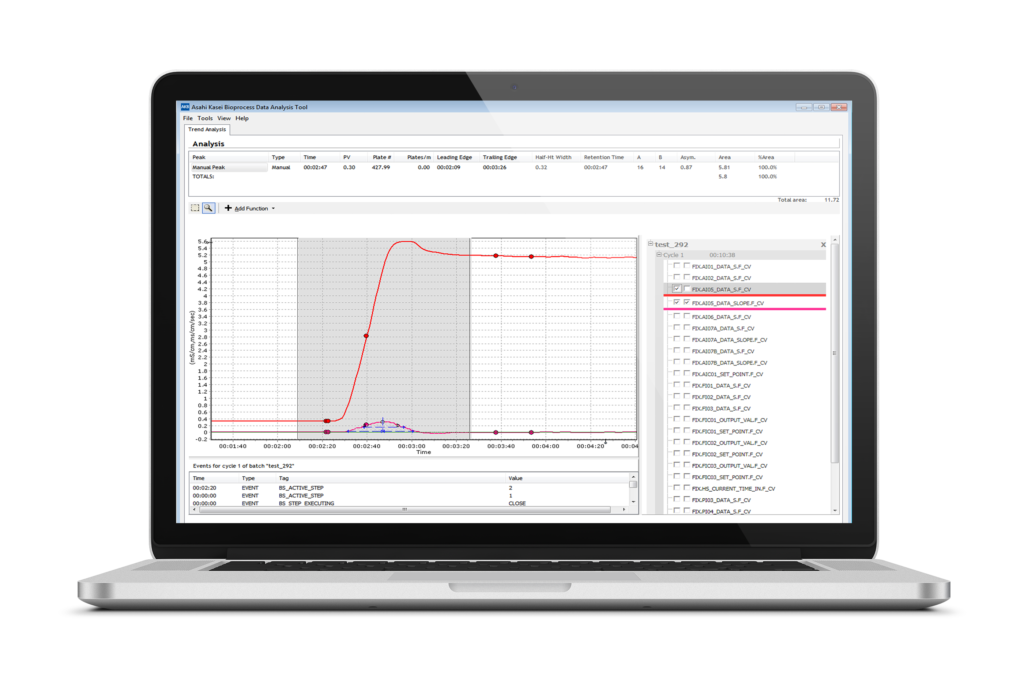

Software Designed For You

Off-the-shelf chromatography systems may provide familiar software, but have rigid hardware constraints; conversely, systems with customized hardware are typically burdened with cumbersome and dated software. You no longer have to compromise.

Equipment designed to respect your manufacturing needs

Product Options

| Catalog No. | Flow Rate Range | Pressure Rating | Typical DAC Column Pairing |

| MPC180 | 18-180 L/h | 20 bar | 15-20 cmi.d. |

| MPC240 | 24-240 L/h | 20 bar | 15-30 cmi.d. |

| MPC360 | 36-360 L/h | 20 bar | 15-40 cm i.d. |

| MPC600 | 60-600 L/h | 20 bar | 20-45 cm i.d. |

| MPC900 | 90-900 L/h | 20 bar | 30-60 cm i.d. |

| MPC1K2 | 120-1200 L/h | 20 bar | 30-80 cm i.d. |

| MPC2K4 | 240-2400 L/h | 20 bar | 40-100 cm i.d. |