Benefits

Save Time, Reduce Risk

The VANTIJ® GPTS enhances efficiency with an in-line spectrometer, providing fast pass/fail results and eliminating offline analysis. It features a QR code scanner, alarms, and automatic pressure control for accurate testing. These improvements save time and ensure proper testing conditions.

Flexibility

VANTIJ® GPTS control units support Planova 15N, 20N, or 35N filters, each with a perpetual software license for one filter type. Units for 15N or 20N can add a second license for flexibility in multi-product environments, while 35N units are exclusive to 35N filters. The system also includes an optional pre-GPT wash phase, automating the transition from wash to filtration without user input.

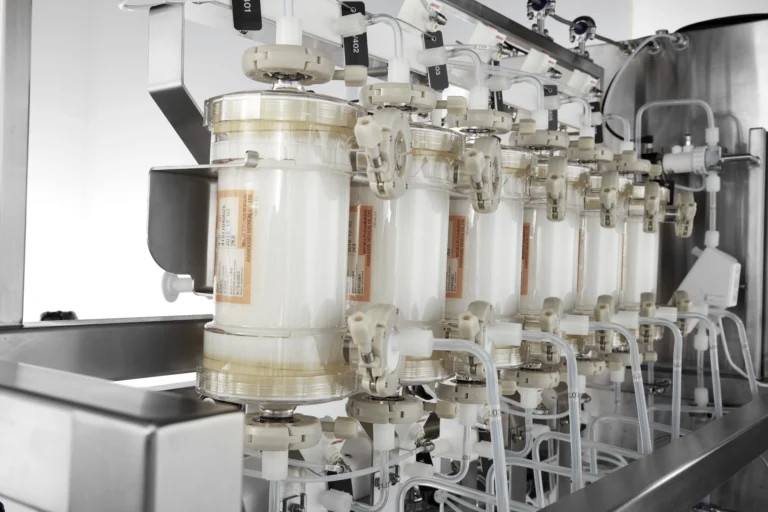

Single-Filter GPTS Mechanical System Description

- Four-port inlet valve manifold (diluted integrity testy solution, air, pre-GPT wash solution, water).

- Dry line detection.

- Planova differential pressure measurement.

- Feed side flow measurement and totalization.

- In-line VIS spectrometer

- Backpressure control valve.

- Fractionation manifold for permeate collection.

- Cleaning by water rinse and air blowdown.

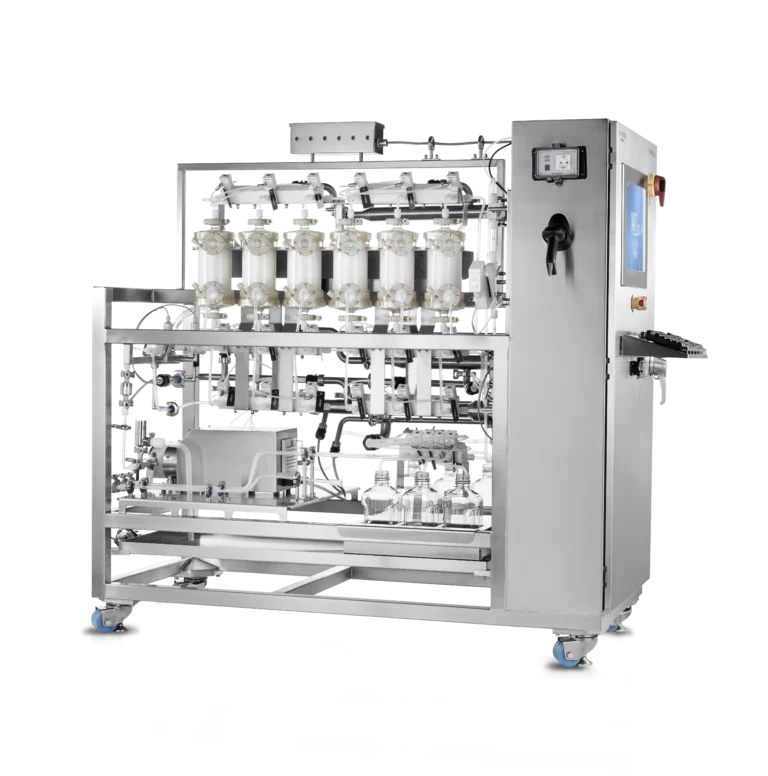

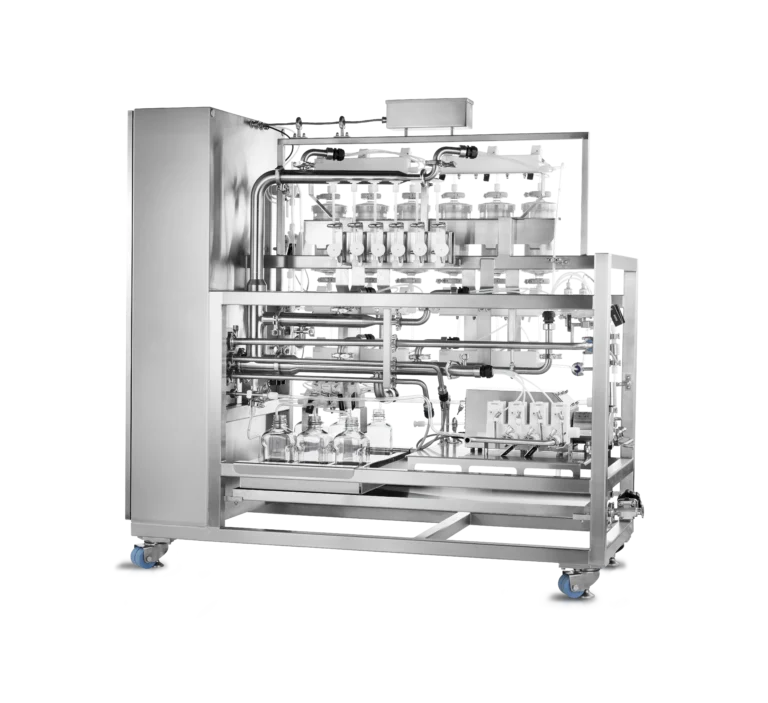

Multi-Filter GPTS Control Units

The 1F GPTS reduces the GPT set-up, operation, and measurement time by over 50% for one Planova 20N filter. The 6F and 10F GPTS units further increase these time savings for 6 and 10 filters respectively, providing significant efficiency for processes using multiple filters or facilities with high filter usage.

- Multi-Filter GPTS units enhance efficiency for batches with three or more filters or facilities using over 100 filters annually.

- Multiple filters can be mounted and processed sequentially, reducing set-up time and labor costs.

GPTS control units are configured to handle Planova 15N, 20N or 35N filters

GPTS control units are configured to handle Planova 15N, 20N or 35N filters