Benefits

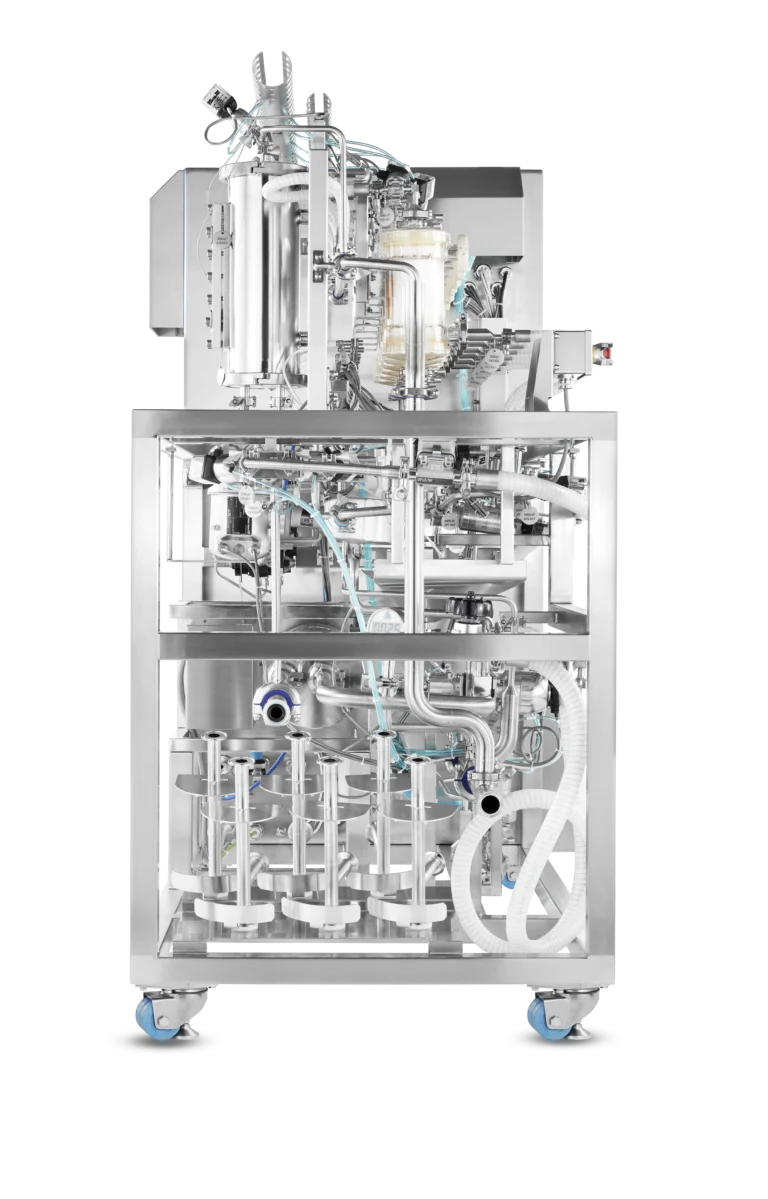

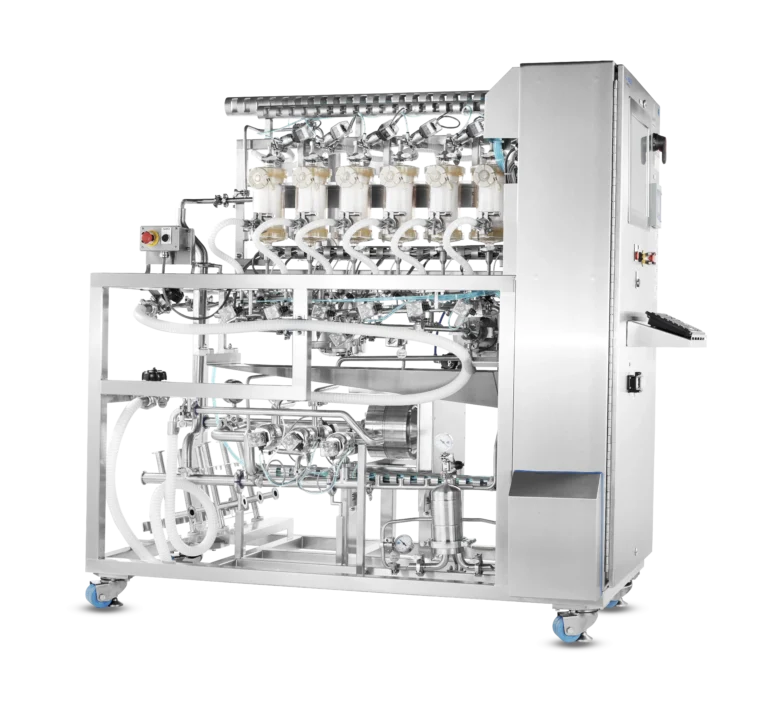

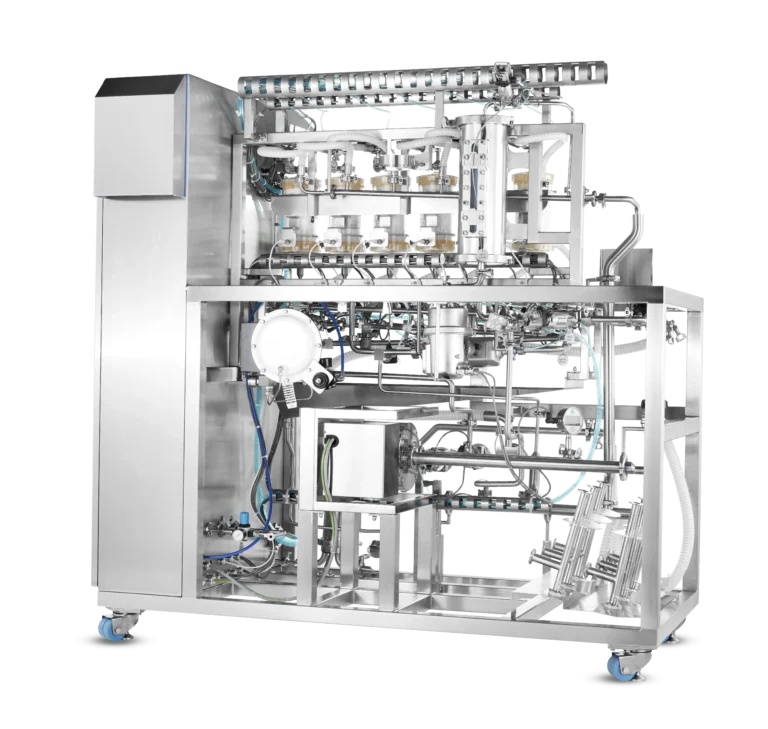

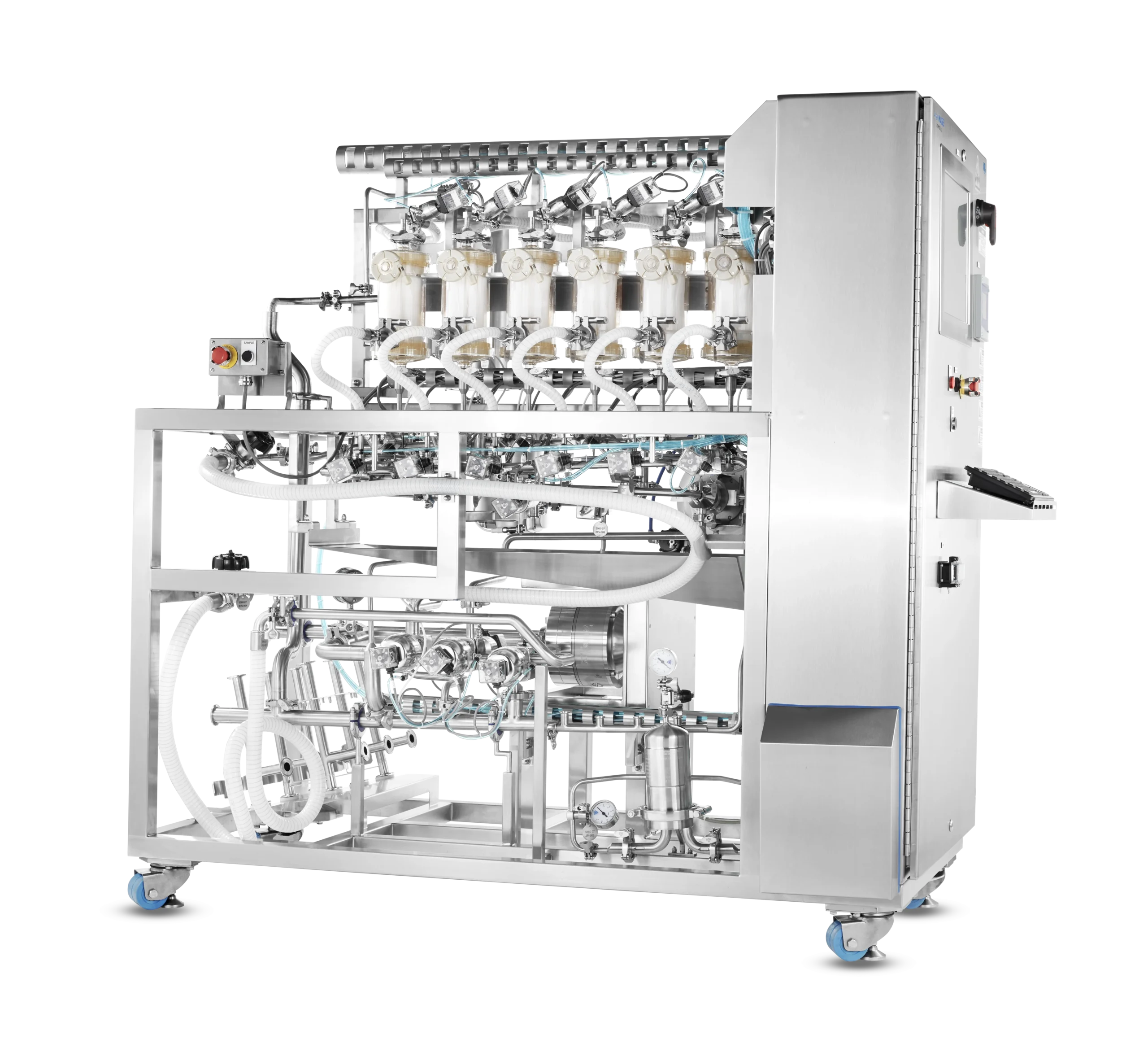

De-risk Your Commercial Scale Virus Filtration

The VANTIJ™ VFS includes several risk-mitigating features and design elements to ensure that your high-value biotherapeutic is safely, reproducibly and reliably filtered batch after batch. Transfer seamlessly between product feed and buffer chase.

Flexibility For Your Process

The VANTIJ™ VFS can be designed for your unique requirements, balancing your current production levels against anticipated future demand. Our ASME-BPE compliant stainless steel systems accommodate feeds from either single-use bags or pressure tanks, allowing buffers and products to be stored in the format of your choice.

System Options:

- Capability to manage both Planova N series and Planova BioEX filters

- Constant pressure or constant flow operation

- Pre-filter

- Bubble trap

- Positioning for visual leakage testing

- Conductivity monitoring Steam-in-place (SIP) configurations

applications

Automation Platform Built For You

Our VANTIJ™ VFS is available with three different automation platforms to match your site requirements, each offering the same functionality.

Zero static valve manifolds minimize pressure loss

Zero static valve manifolds minimize pressure loss