Benefits

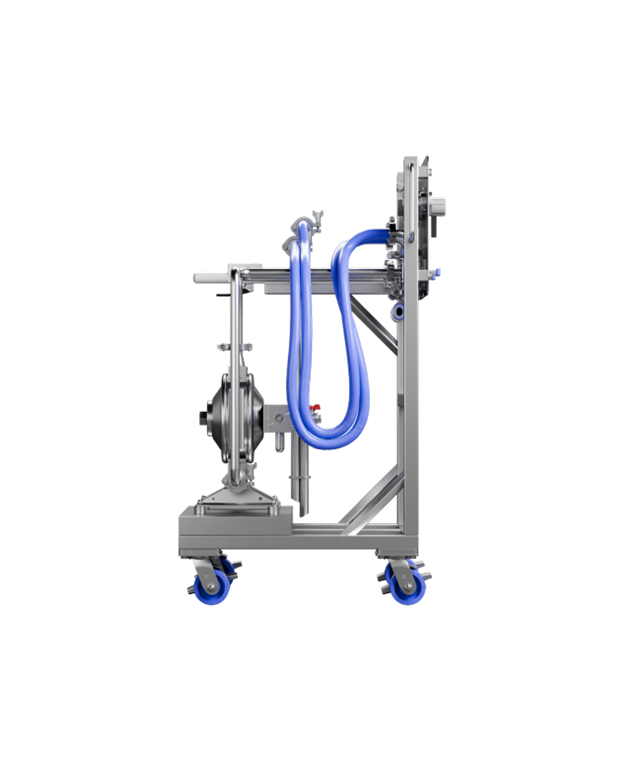

Industrial, Sanitary or Hygienic Flow Paths

For oligonucleotide or microbial-derived protein purifications that mainly utilize aqueous mobile phases with limited use of organics, or for highly potent active pharmaceutical ingredient (HP-API) purifications where minimized system hold-up is desired, our sanitary or hygienic flow paths are attractive options. Alternatively, our industrial flow path is the most cost-effective for small molecules.

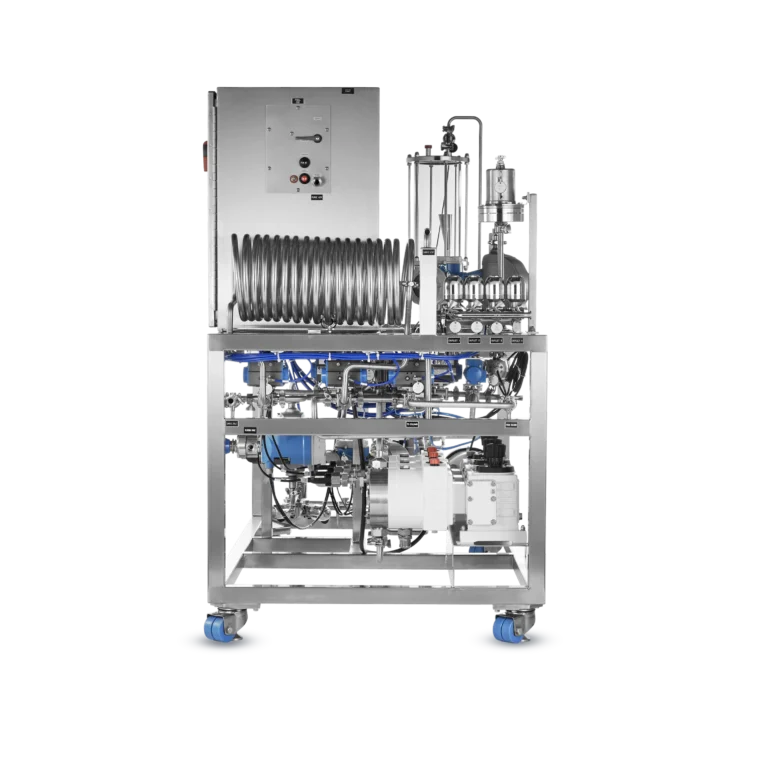

Gradient Mixing Technologies

Classic Low Pressure Gradient Mixing

- Control valves proportion eluents

- Mixing is on low pressure side of pumps

Controller type: Adaptive PAT control or flow control

Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

Enhanced Low Pressure Gradient Mixing

- Control valves proportion eluents

- Mixing is on low pressure side of pumps

Controller type: Adaptive PAT control or flow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

High Pressure Gradient Mixing

- Pumps proportion eluents

- Mixing is on high pressure side of pumps

Controller type: Flow control

Eluent supply: Unpressurized/minimally pressurized

Turndown: Up to 90X

Accuracy: ± 2%

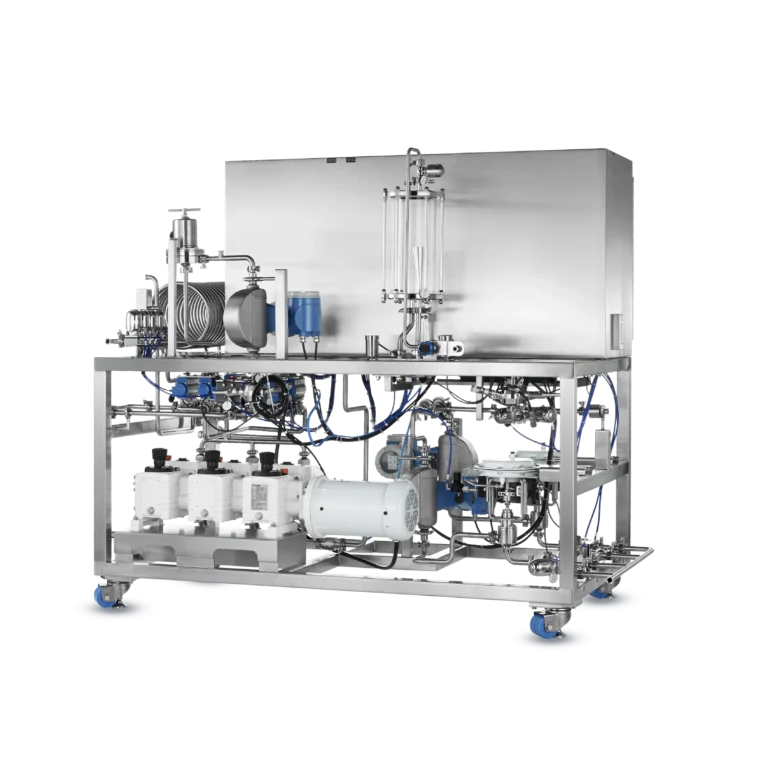

Ternary Pressure Gradient Mixing

Three control valves proportion eluents

Mixing is on low pressure side of pumps

Ideal for combination aqueous/organic elutions

Controller type: Adaptive PAT control or flow control

Eluent supply: Pressurized

Turndown: Up to 30X

Accuracy: ± 2%

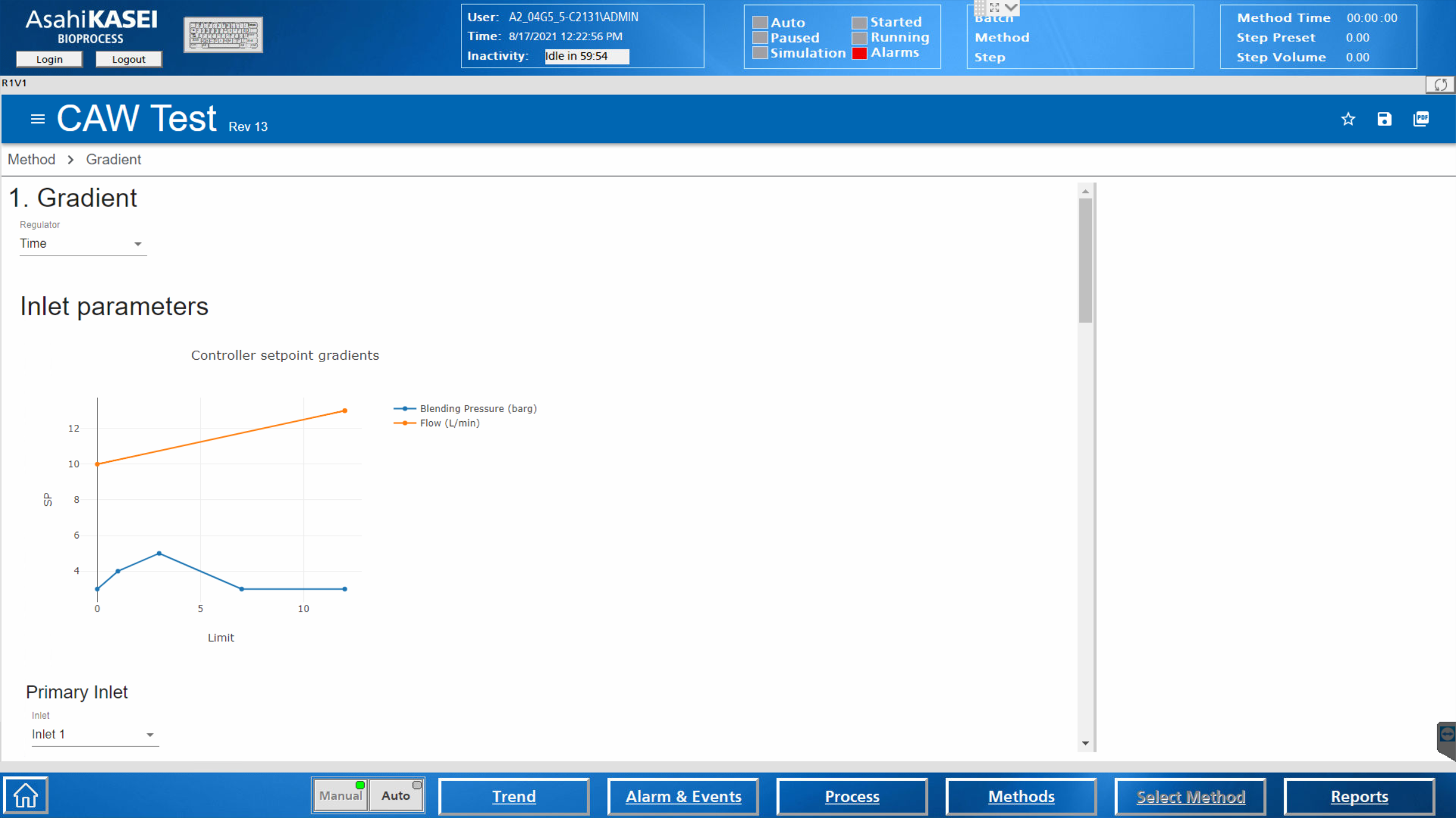

Gradient inlet parameters.

Gradient inlet parameters.