Benefits

Patented Pro-Yield™ Recirculation Blender Technology

All MOTIV® systems include our patented, Pro-Yield recirculation blending technology to shorten the buffer adjustment response rate. The dynamic, single-pass mixer efficiently blends your liquid streams inline – regardless of flow rate or viscosity – to allow for a faster setpoint target and faster washout volumes.

Efficient Buffer Production

With MOTIV® 3, you can leverage stock buffer concentrates and pH modifiers to produce high-quality buffers on demand, within as short as 15 seconds from system start-up. After use, the system can be rinsed down in under a minute.

Continuous Processes

Create subroutines and stack recipe segments to produce multiple process buffers unattended and sequentially, just-in-time to feed continuous chromatography systems.

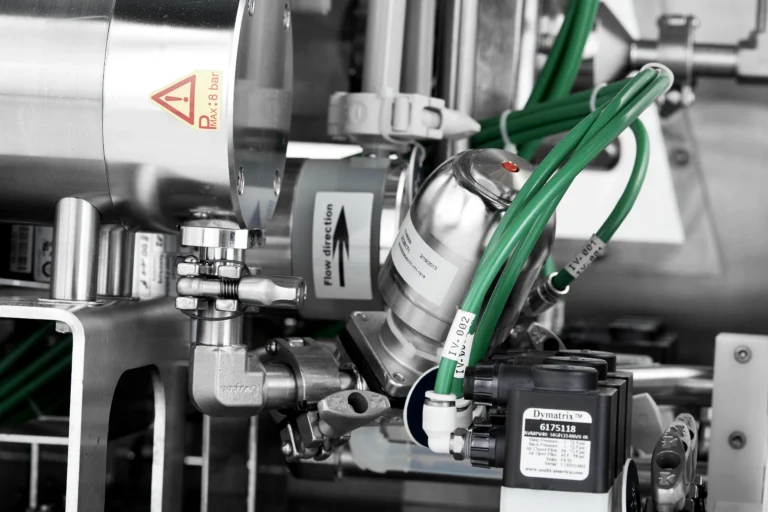

One larger pump is used to deliver the dilutant, typically WFI or purified water, into the system

One larger pump is used to deliver the dilutant, typically WFI or purified water, into the system

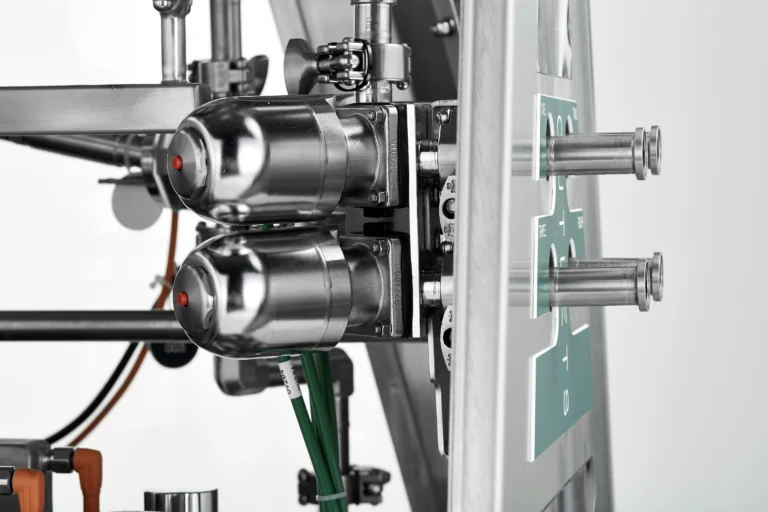

Two smaller pumps can deliver buffer concentrate and an acid or base modifier, respectively

Two smaller pumps can deliver buffer concentrate and an acid or base modifier, respectively