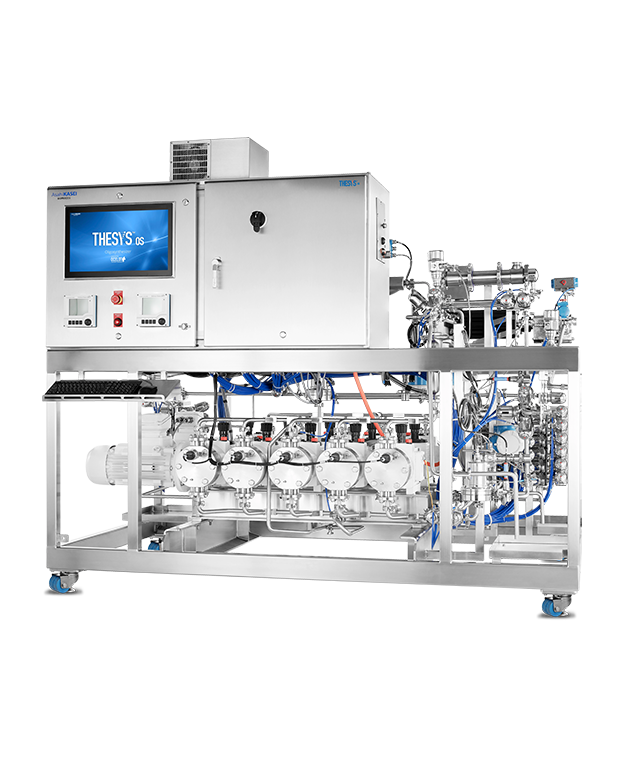

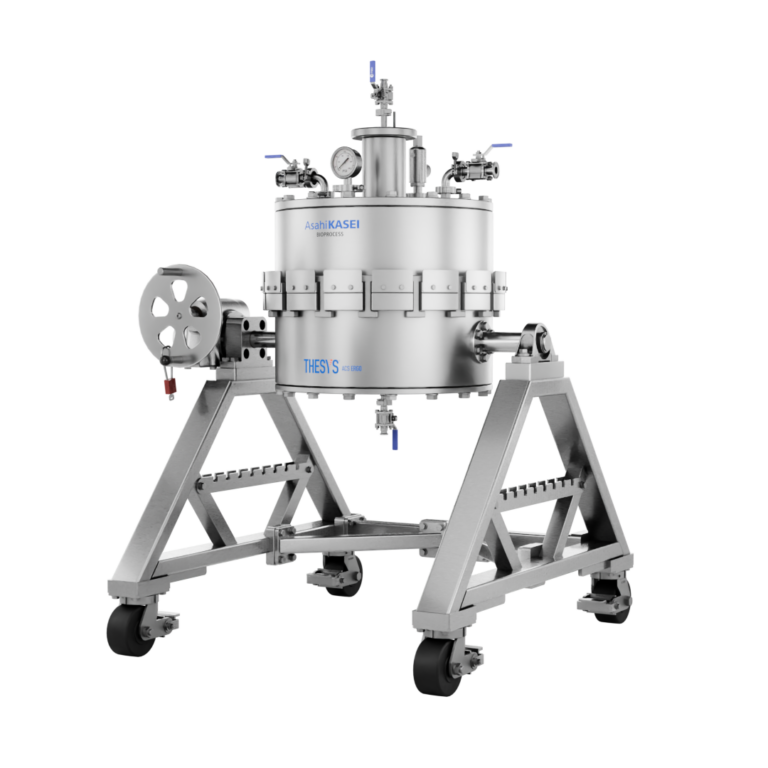

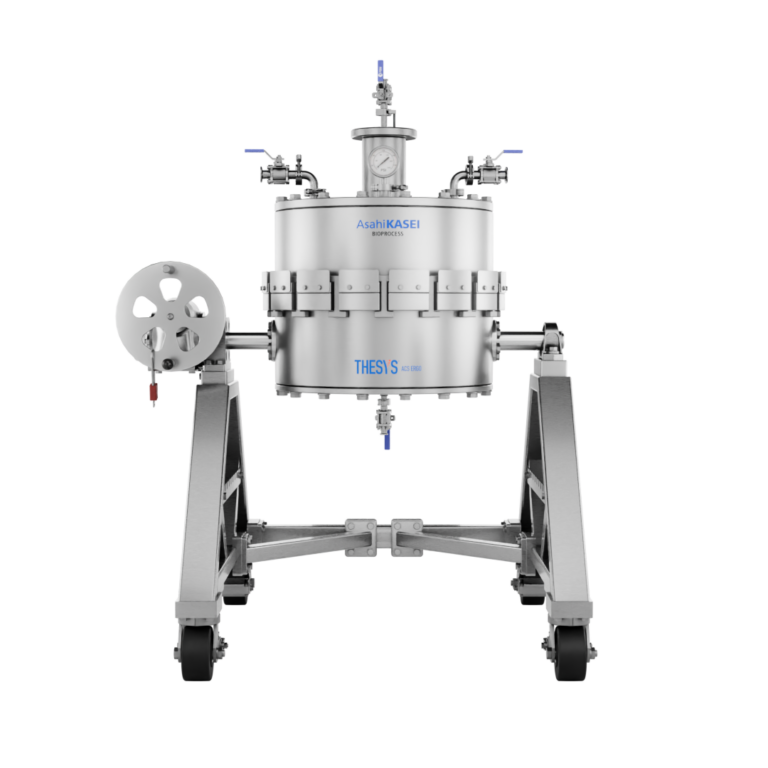

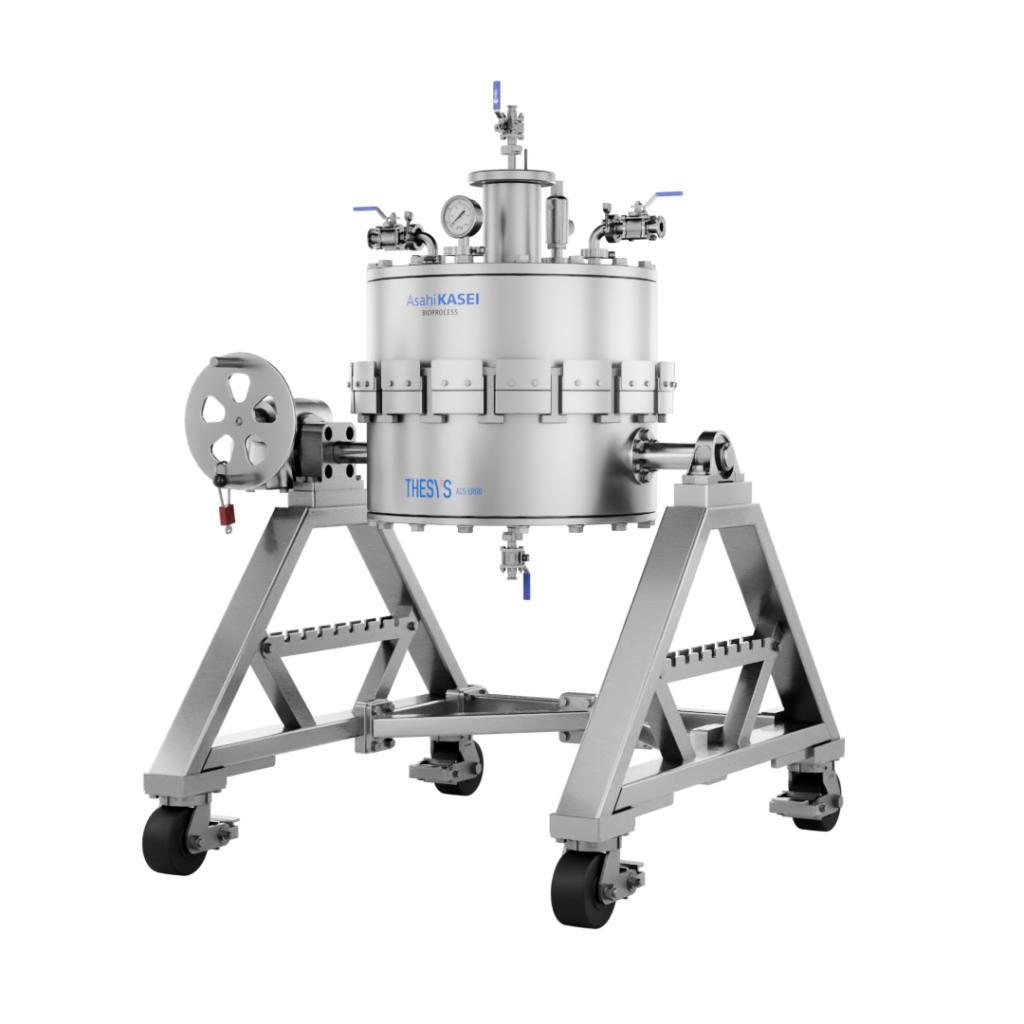

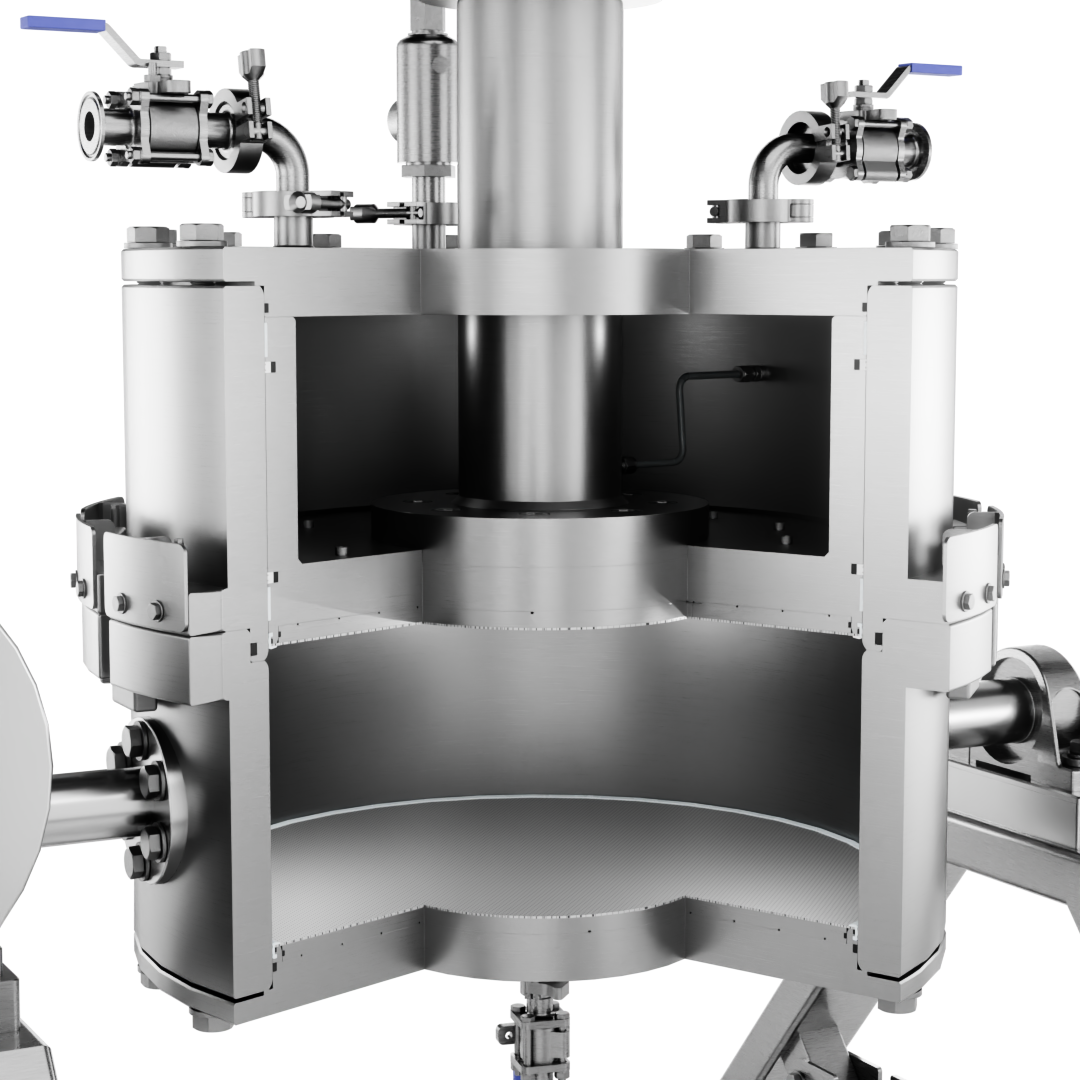

Key Features

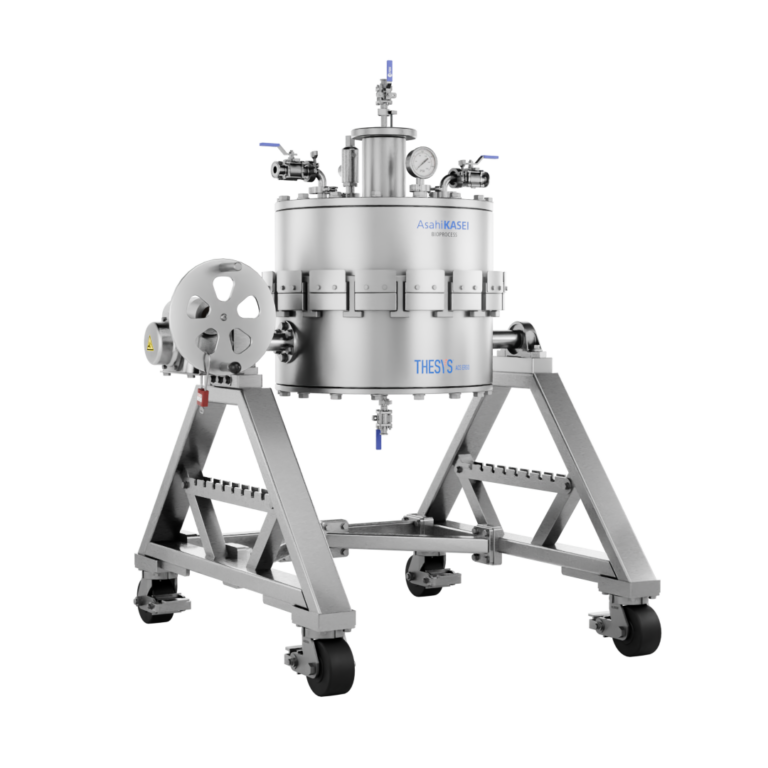

- Bolt free design (innovative I-bar format) to improve efficiency of removing the top of the column to access the process chamber.

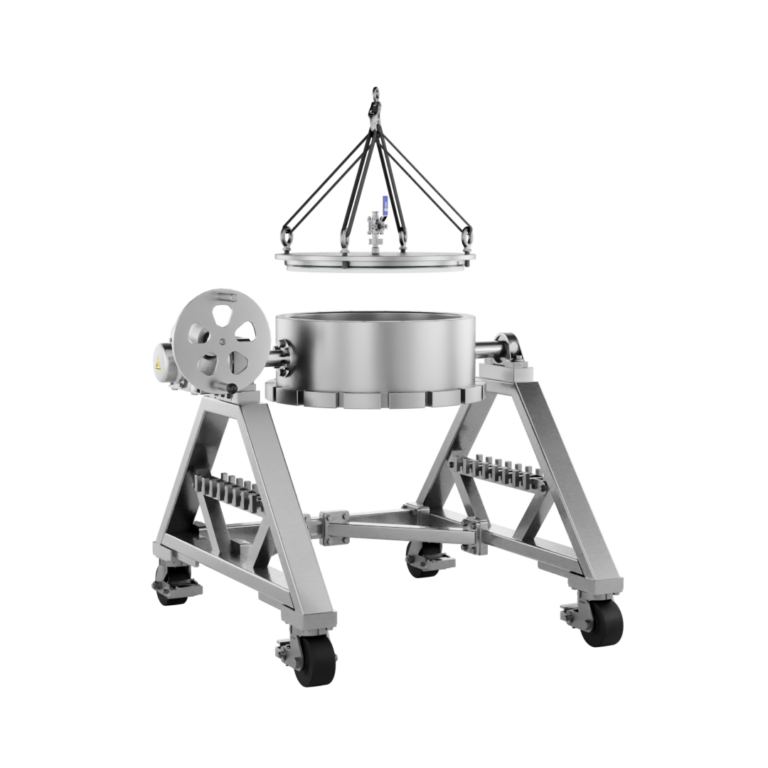

- Unique frame with ergonomic handle assembly to facilitate smooth, safe unpacking and cleaning.

- Capable of handling columns up to 100 cm i.d.

- Capable of locking at 6 to 9-degree intervals with built-in safety mechanisms to prevent accidental rotation.

- Dynamic piston movement, to allow for simpler bed height adjustment.

- Minimized footprint to integrate into manufacturing floor seamlessly.

- Safe, lockable casters.

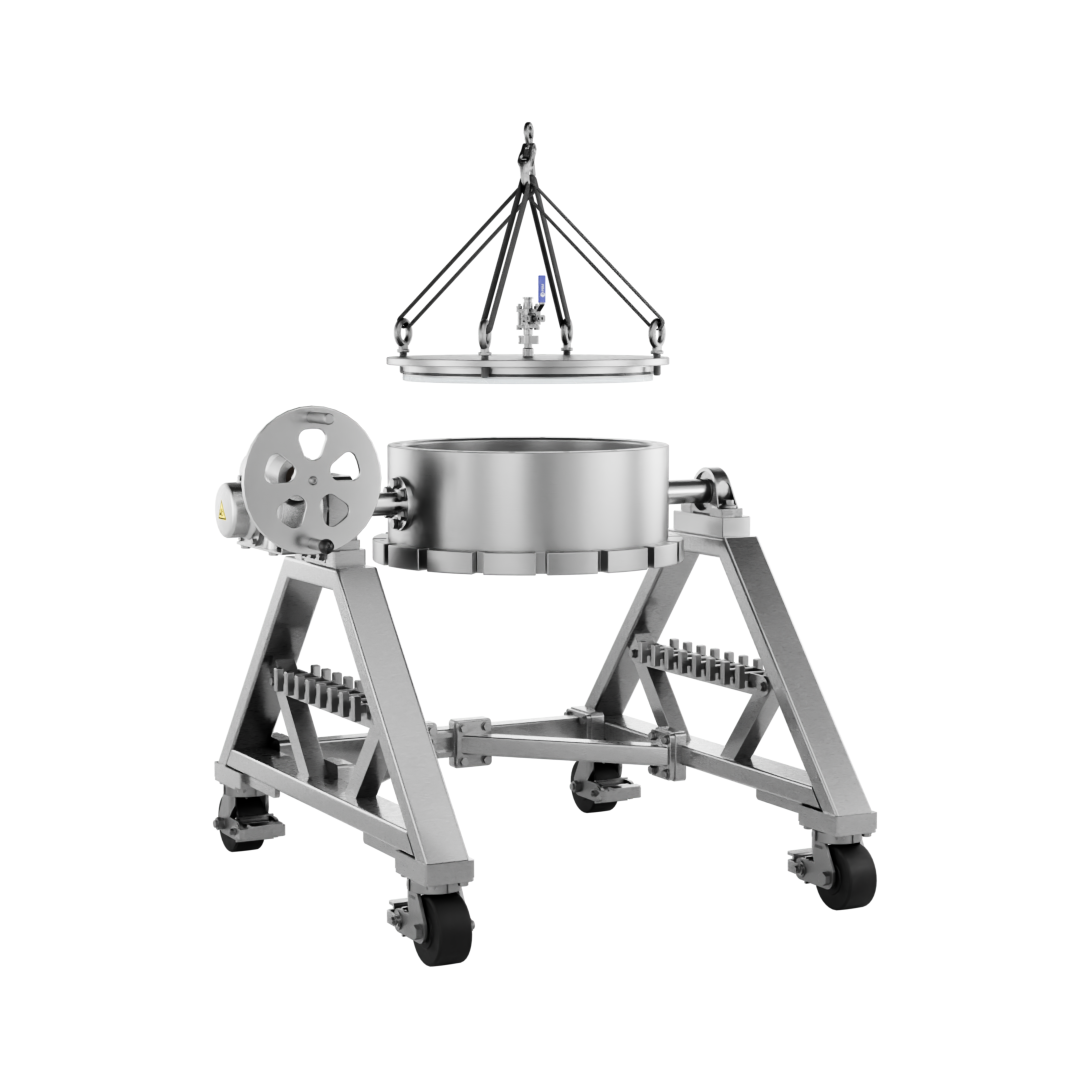

Smooth Column Changeover in 10 Easy Steps

- Secure column in vertical position with upper section attached to overhead hoist.

- Remove I-bars and store in convenient storage location on column frame.

- Lift upper section with overhead hoist.

- Unlock the rotation mechanism.

- Tilt column for discharging solid support and cleaning.

- Position column upside down and remove bottom plate with overhead hoist.

- Change frits and seals on upper section and bottom plate.

- Replace bottom plate and charge new solid support into column.

- Replace upper section by lowering back into place and reinstall I-bars.

- Lower piston to achieve desired bed height and prepare for next batch.

Bolt-Free Design: Simplifies disassembly, cleaning, and reassembly, reducing downtime between batches.

Bolt-Free Design: Simplifies disassembly, cleaning, and reassembly, reducing downtime between batches.

Dynamic Piston Movement: Allows for easy and precise setting of the fixed bed height, enhancing efficiency during setup.

Dynamic Piston Movement: Allows for easy and precise setting of the fixed bed height, enhancing efficiency during setup.