Benefits

Thoughtful Design

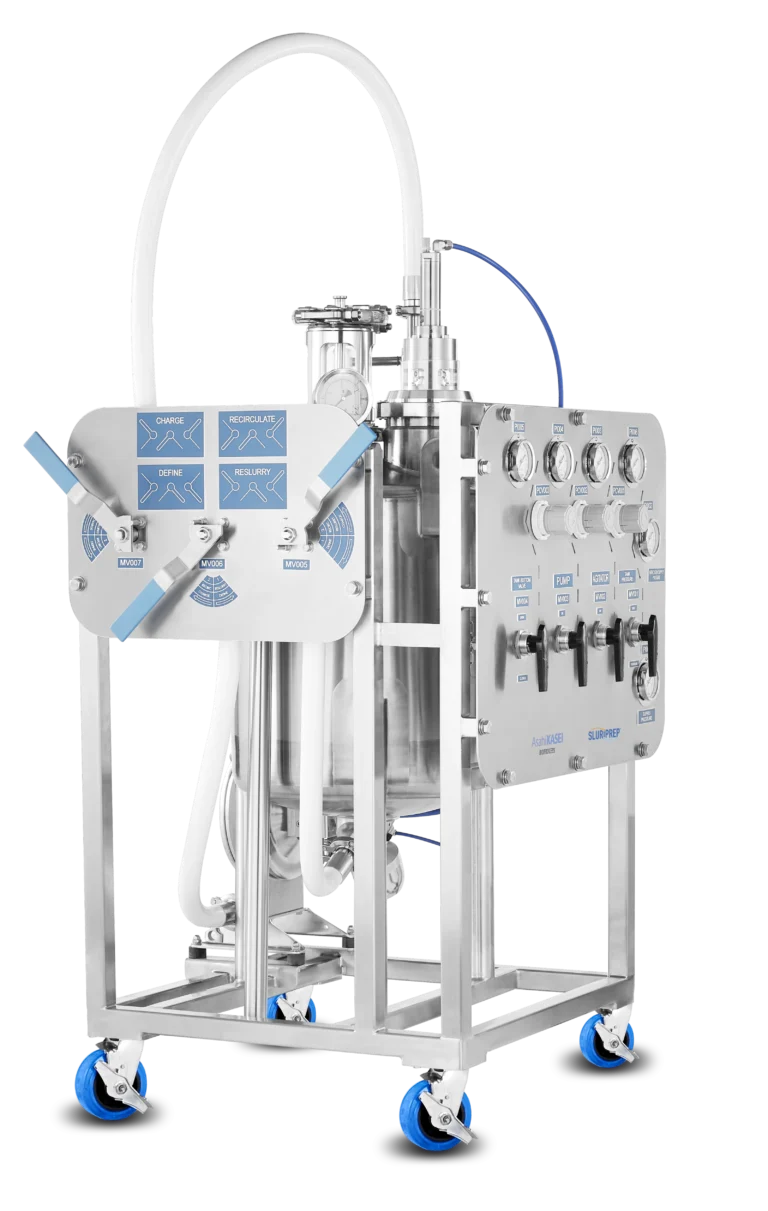

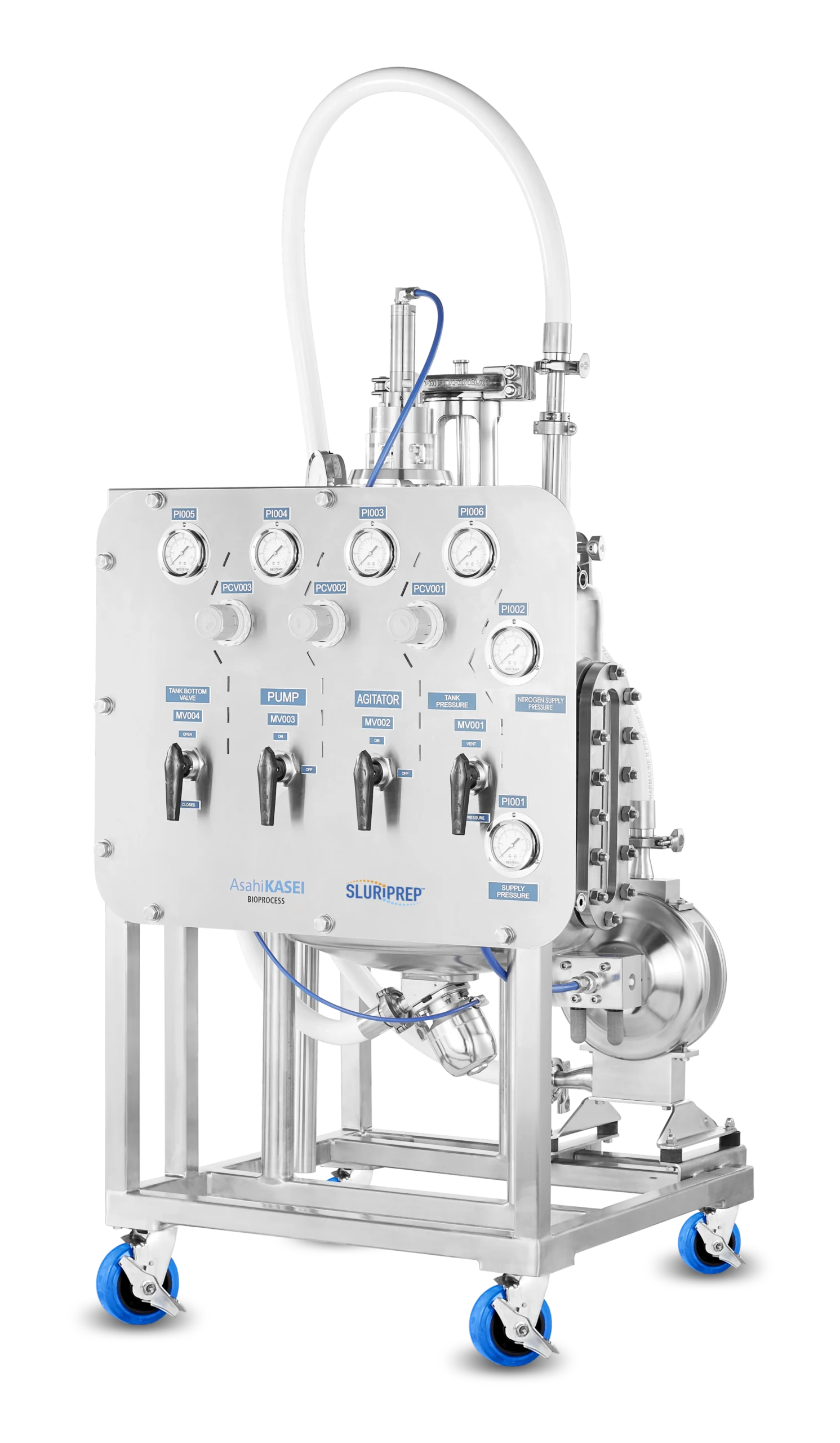

The multi-function design of the SPS permits slurry to be mixed, de-fined, recirculated and charged into DAC LC Columns. The unit is also fully non-electrical, allowing seamless installation into hazardous areas without additional costs for electrical protection or controls validation.

Standard features include:

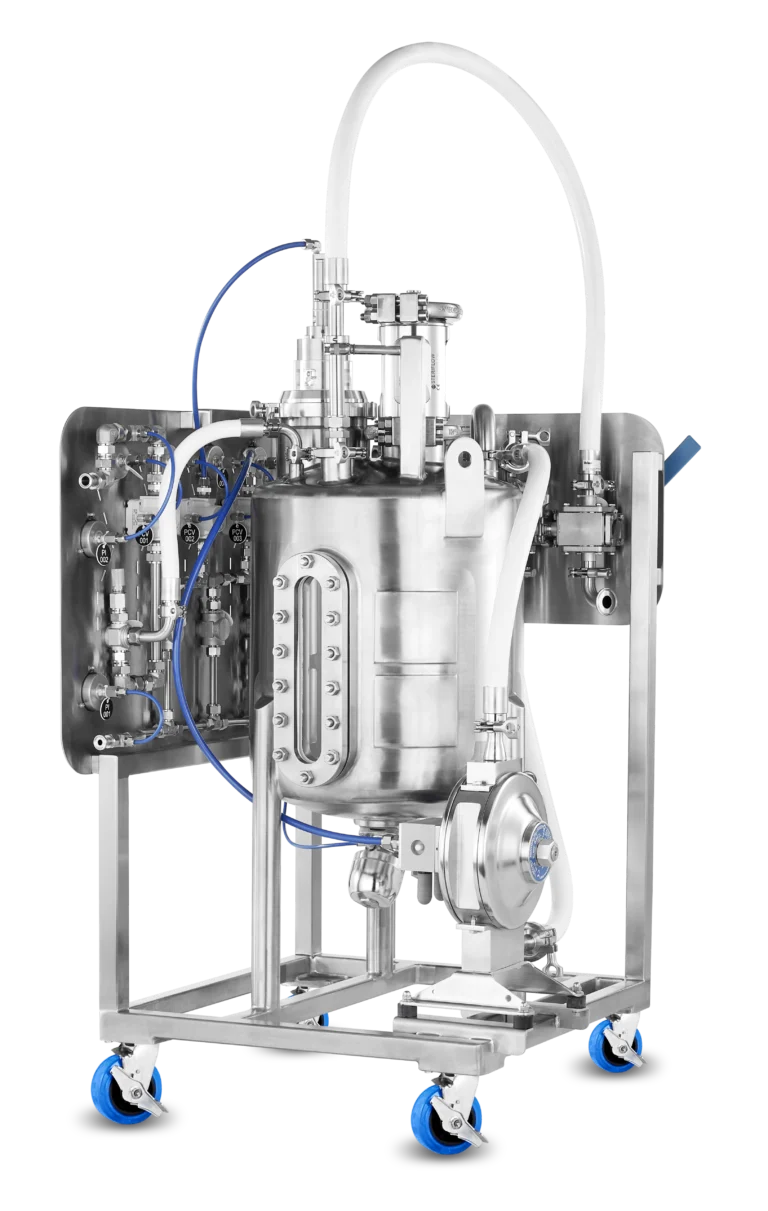

- Electropolished 316L SS mixing vessel.

- Pneumatic control panel and liquid control panel for manual operation.

- Agitator with speed control.

- Sidewall sight glass for monitoring slurry level.

- Integral decanting dip tube for de-fining.

- Slurry transfer pump with speed control.

- De-fine, Reslurry, Recirculate and Charge modes.

- ASME code stamp (for US installations).

- CE Pressure Equipment Directive compliant (for EU installations).

Prepare for Column Packing in 7 Easy Steps

- Fill SPS vessel with slurry buffer as recommended by the media manufacturer.

- Add media from your supplier’s containers.

- Gently mix the media into a slurry with the agitator.

- Allow the media to briefly settle in the vessel for de-fining.

- Decant fines from the supernatant; repeat steps 4 and 5 as necessary.

- Add more slurry buffer and recirculate vessel to reslurry media.

- Connect to your empty column and charge the slurry using the slurry transfer pump.

Pneumatic control panel

Pneumatic control panel

Agitator with speed control

Agitator with speed control