Benefits

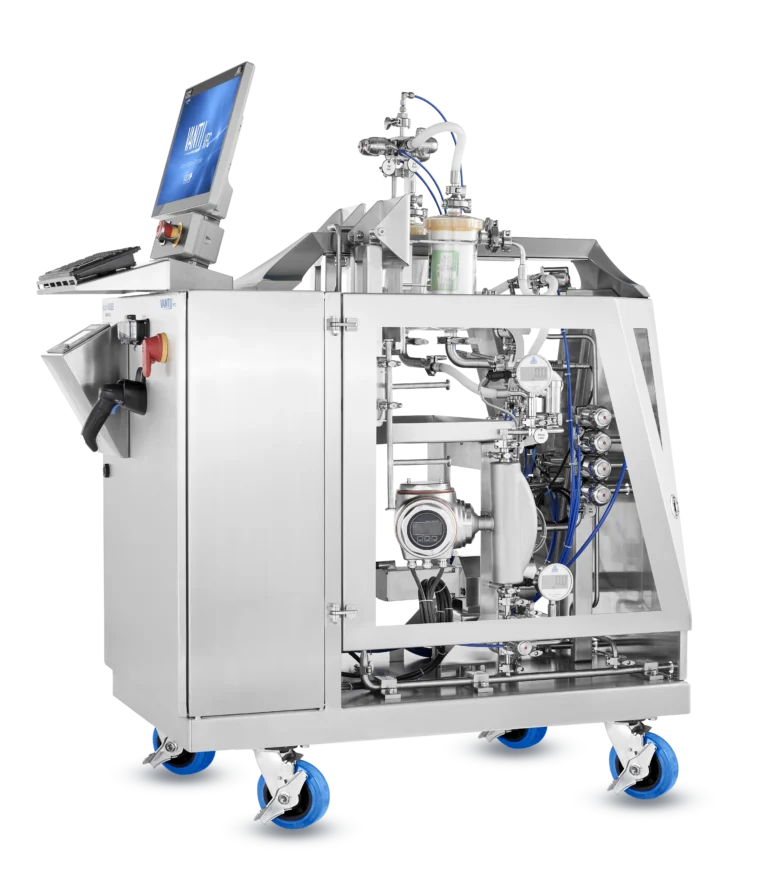

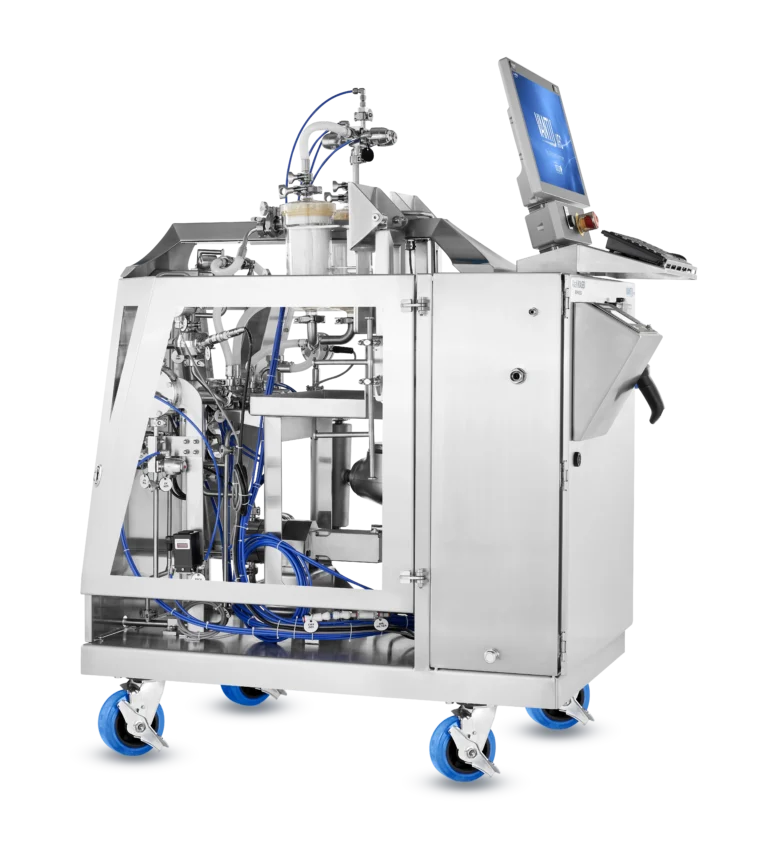

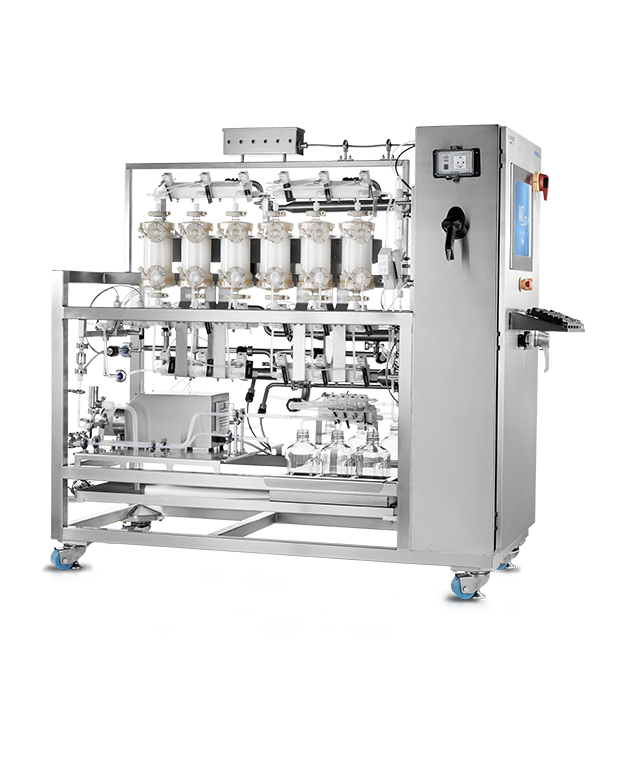

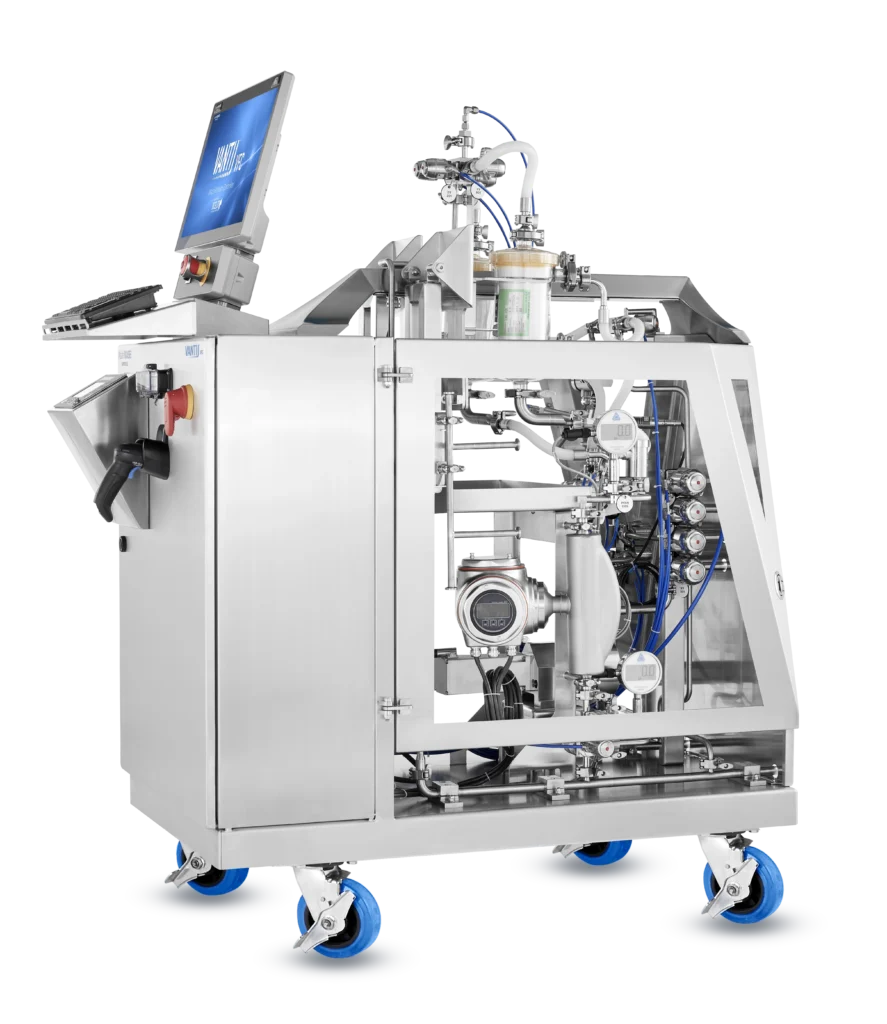

VANTIJ® VFC

For problem-free virus filtration, our newly updated VANTIJ® VFC automates your virus filtration unit operation. With a wider operating range, 21CFR Part 11 compliant automation platform, and integrated visual leakage testing, the VANTIJ® VFC enables reliable virus filtration for Planova 15N, 20N, 35N, S20N, FG1, and BioEX filters in a small format that is ideal for both clinical and commercial cGMP manufacturing areas.

Compact and ergonomic footprint: 1140 mm (45 in.) length x 810 mm (32in.) width x 1630 mm (64 in.) height

Compact and ergonomic footprint: 1140 mm (45 in.) length x 810 mm (32in.) width x 1630 mm (64 in.) height

Modest Size, Bold Functionality

The VANTIJ® VFC is the most compact, fully automated virus filtration system on the market. With a footprint of a modest 660 mm x 1219 mm (26 in. x 48 in.), the VANTIJ® VFC can be installed in almost any downstream processing area. By incorporating the capability to perform integrity testing, the VANTIJ® VFC permits simplified implementation of Planova and BioEX filters in your process.

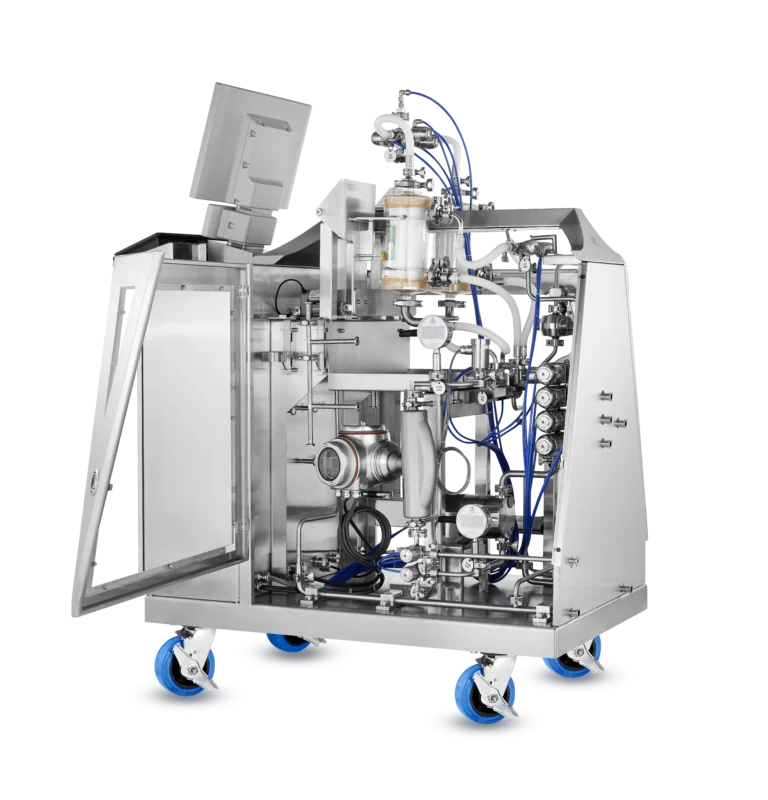

Steps performed on the VFC:

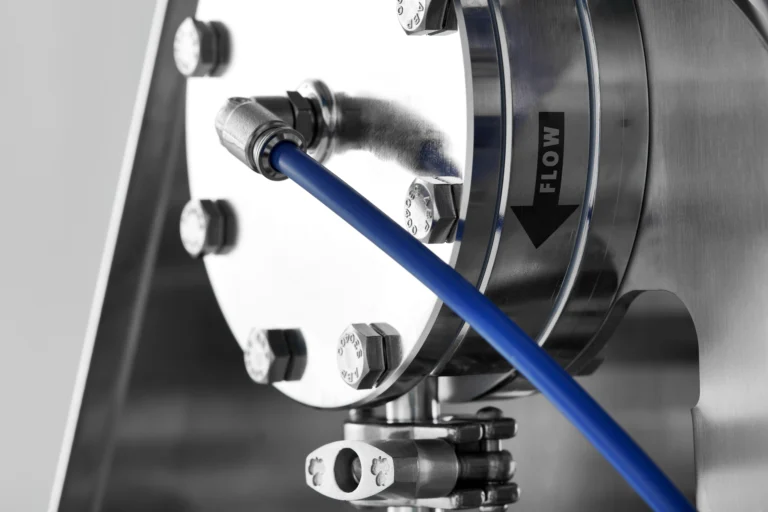

- Pre-use visual leakage test

- Pre-use flush

- Product filtration

- Product recovery flush

- Post-use visual leakage test

- CIP

applications

Automation For Today

Our robust VANTIJ® VFC automation platform permits intuitive configuration of all virus filtration process steps. Barcode scanning allows error-free filter identification.

Other features include:

- Recipe generation and storage

- Live and historical trending of all analog signals

- Alarming

- Audit trail

- Electronic signature option

- Batch report generation

- Data export