Benefits

Pack Your Column in Minutes

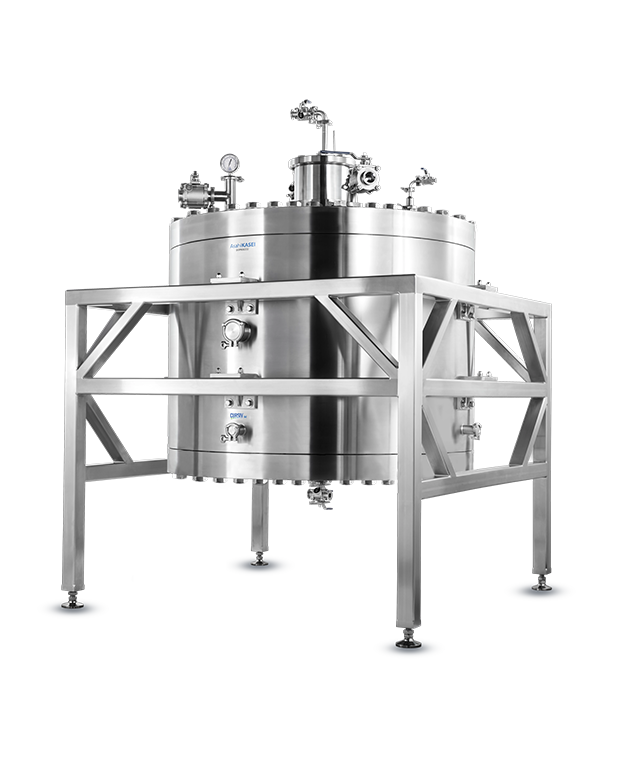

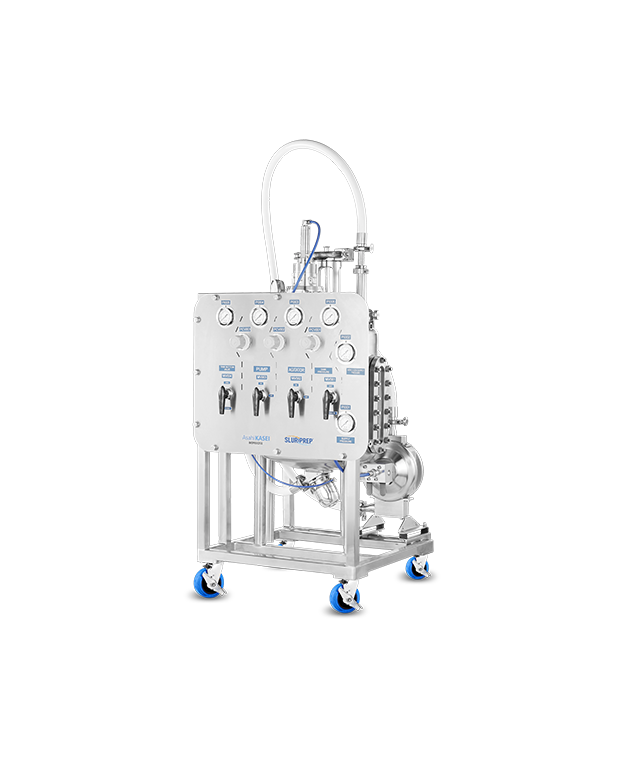

Transfer slurry into the column and reproducibly piston-pack your chromatography media in minutes. When it is time to unpack your column, use the same piston to easily push the media out of the column.

Active Flow Distribution

CAD-modeled “active” flow distribution generates uniform dispersal of your product and eluents across the entire column surface, even for columns packed with short bed heights, resulting in maximum chromatographic resolving power.

Greater Flexibility

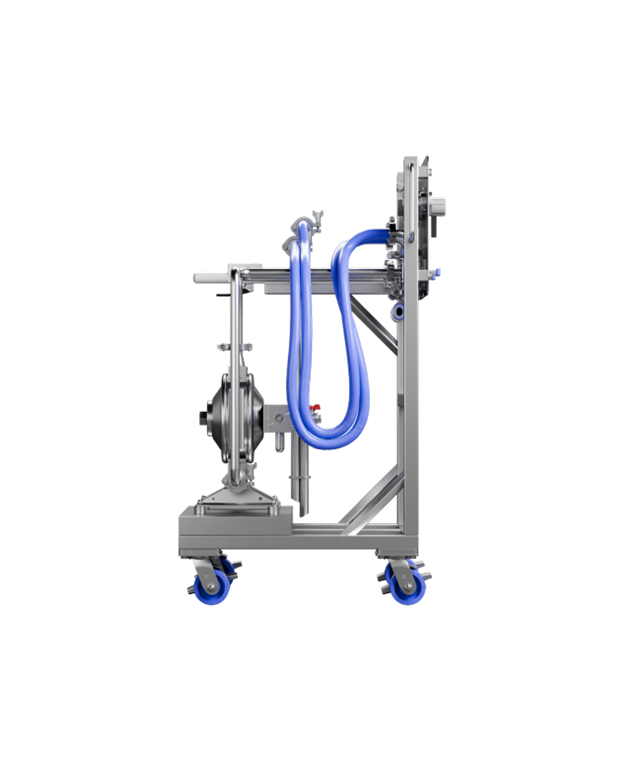

Our DAC MPLC Columns are available with fully separated hydraulics. Columns with similar pressure ratings and internal diameters can be operated with a single hydraulic cart when the columns are not in use simultaneously. This unique feature reduces capital costs and maximizes resource allocation.

applications

Enjoy the Freedom of Customization

Several options are available so that you can customize your column to your particular application needs:

Features include:

- Electropolishing

- ASME code stamp

- CE Pressure Equipment Directive compliance

- IQ/OQ qualification package

Fully moveable piston to achieve precise bed height

Fully moveable piston to achieve precise bed height

Many oligonucleotides or small protein purification generate back pressure less than 20 bar. When a 20 bar column will be sufficient, MPLC columns provide the benefits associated with dynamic axial compression.

Many oligonucleotides or small protein purification generate back pressure less than 20 bar. When a 20 bar column will be sufficient, MPLC columns provide the benefits associated with dynamic axial compression.