Benefits

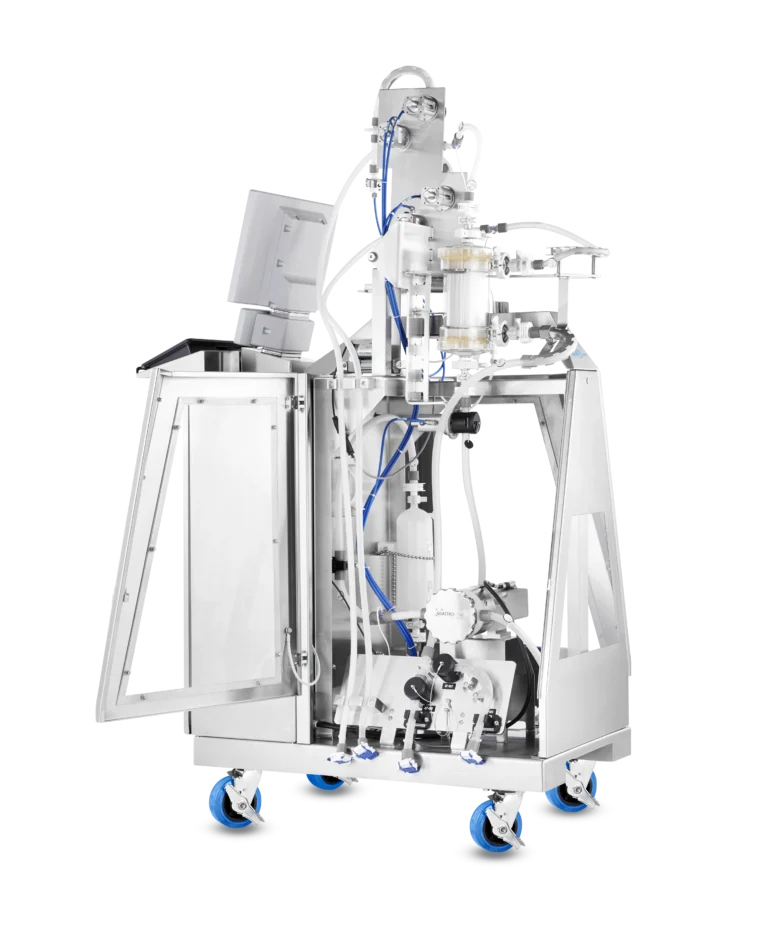

Single-Use Means Flexibility & Reliability

In today’s clinical and multi-product manufacturing facilities, having flexibility for fast changeover is paramount.

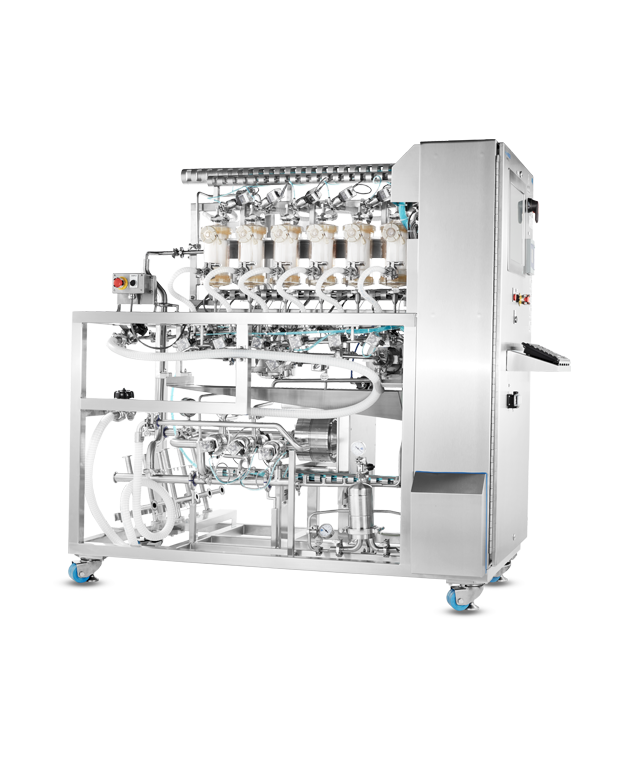

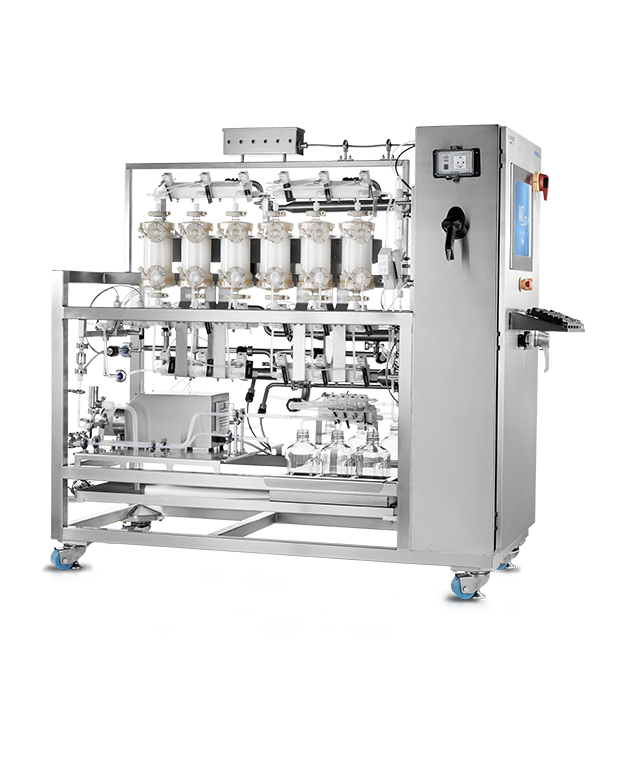

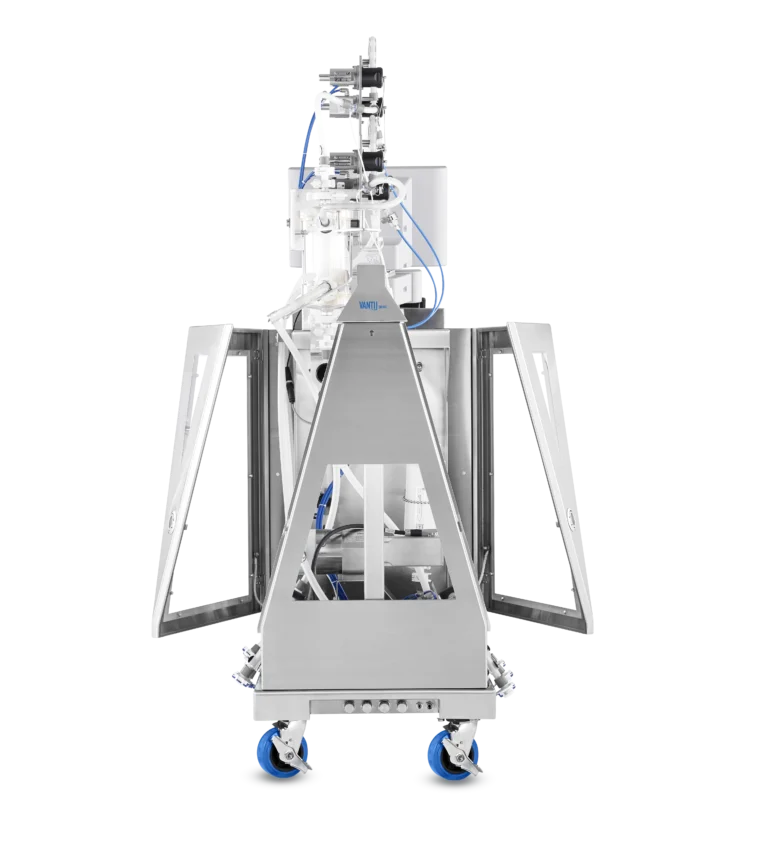

Bold Design, Simple Functionality

With a footprint of a modest 712 mm x 1067 mm (28 in. x 42 in.), the VANTIJ SU-VFC can be installed in almost any downstream processing area and is fully 21 CFR Part 11 compliant. Universal gamma-irradiated tubing sets can be used with our Planova 15N, 20N, 35N, S20N, FG1, and BioEX filters. By incorporating the capability to perform the visual leakage test (VLT), the VANTIJ SU-VFC permits simplified implementation of Planova filters in your process.

Sample Operational Program

- Install tubing set

- Tare pressure sensors

- Pause

- Prime all inlets

- Prime pre-filter (optional)

- Flowmeter verification (optional)

- Pre-use VLT

- Pre-use flush upflow

- Pre-use flush filtrate

- Filtration

- Recovery flush (optional)

- Post-use VLT

- Shell drain

applications

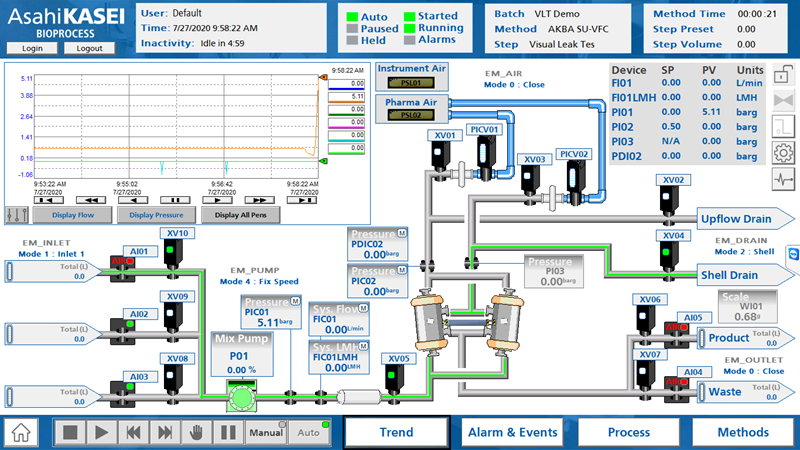

Mitigate Risk with Intuitive, Customized Automation

The VANTIJ® SU-VFC includes several risk-mitigating features and design elements to ensure that your high-value biotherapeutic is safely, reproducibly and reliably filtered batch after batch. OCELOT® System Control – our universally compatible automation platform – allows for intuitive configuration of all virus filtration process steps.

Universal gamma-irradiated tubing sets

Universal gamma-irradiated tubing sets

Our automation is built to your specifications and will work with existing plant-wide systems.

Our automation is built to your specifications and will work with existing plant-wide systems.